DECOPUR® for crystal-clear and self-healing surfaces

Together with the KURZ subsidiary Schöfer, we have developed DECOPUR®: a process with which components produced via IMD, Hot Stamping, PMD, and Insert Molding can be flow-coated with PUR. This creates components with integrated features for autonomous road user communication, front designs specially for electric vehicles, and a state-of-the-art crystal design for the interior. With DECOPUR®, front panels with intricate geometries can be formed right in the same machine clamping unit before multiple decorations are directly applied to them. Premium designs are applied to plastic surfaces. In the same manufacturing step, the entire component part can be flow-coated with polyurethane (PUR). All three manufacturing steps can be bundled, forming an extremely strong bond between the layers.

- Together with the plastic compound and in the same injection molding process, the substrate bearing the motif is pressed directly into the wall of the machine cavity.

- At the set temperature in the machine, the wafer-thin decorative substrate coating dissolves and forms an extremely strong bond with the plastic surface.

- In the next step in the same machine pass, the piece is flooded with polyurethane (PUR).

- This creates injection molded parts and components boasting premium designs under a crystal-clear PUR surface.

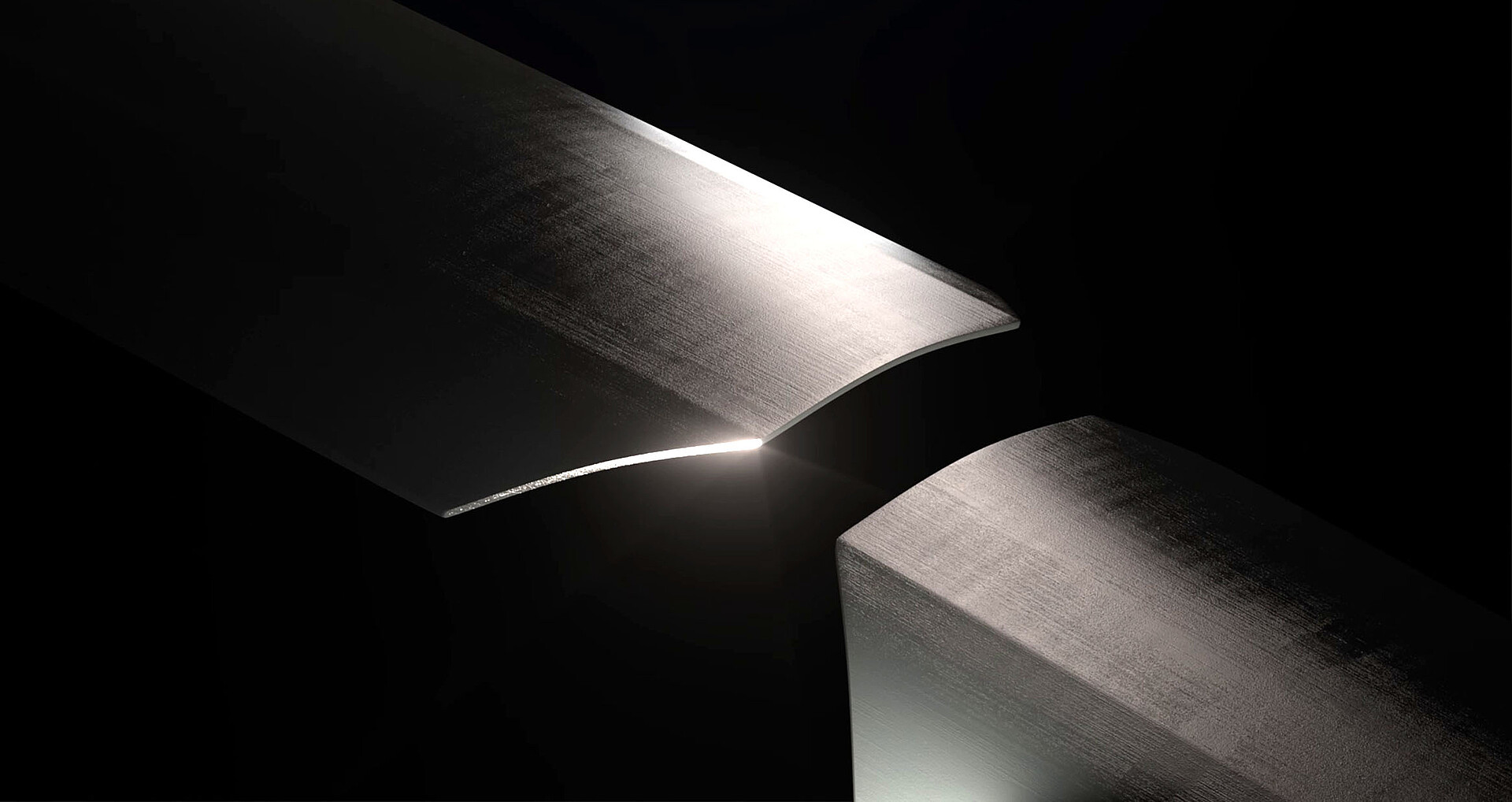

- The crystalline, high gloss finish dramatically showcases the colors, lines, patterns, and structures of the decoration. In particular, this innovative technology delivers unrivaled 3D effects. The decoration acquires an unprecedented plasticity and breathtaking depth effect.

- Because surfaces are completely coated with PUR, they boast self-healing features in case they are scratched, cracked or damaged.

DECOPUR® front panels reinterpreted

These innovations in the DECOPUR® technology from KURZ have won the SPE Award 2024. The PUR layer has been reduced to 0.3 mm and can now also be used for various plastic substrates.

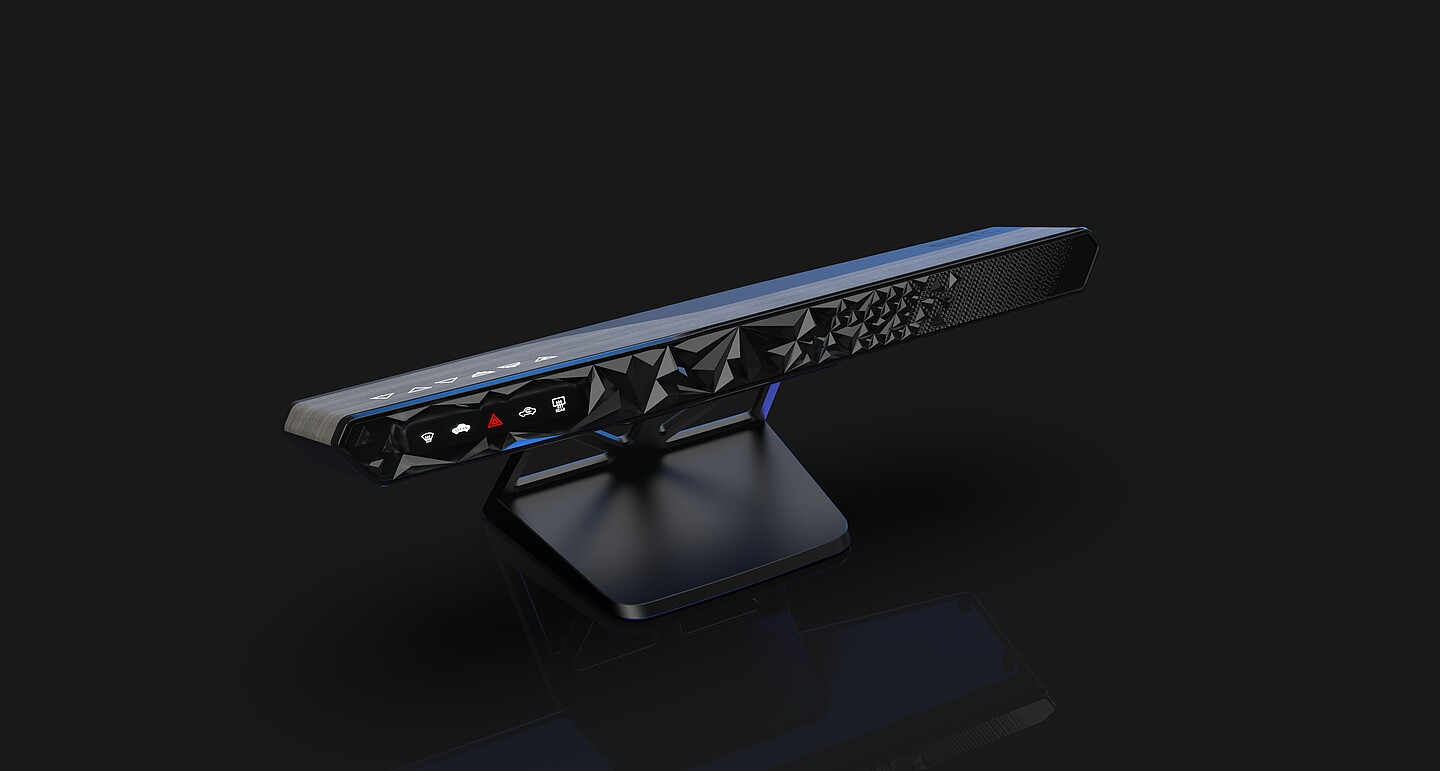

Dashboards and center consoles reinterpreted

This design concept already sets the trends of tomorrow: Crystal design in vehicle interiors. The top of the component can be individually designed using the wide range of IMD decoration design options: From shy tech design with integrated touch function, to seamless ebony surface. Integrated operating functions come alive as soon as the interface is activated via touch or gesture control. Then the complete functionality of the component is revealed. Backlighting and haptic feedback give the user confidence and orientation. The highlight of this concept: The cover with its crystalline structure and multi-light design becomes an absolute highlight with DECOPUR® technology.

Project partners

Advantages

- Supports autonomous driving functions

- Crystal-clear, high-gloss surfaces, and stunning depth effects

- Adhesion-resistant and durable coatings

- Very robust and weather-resistant surface reduces service and maintenance requirements.

- Also suitable for exterior use

- Self-healing surface

- Wide variety of designs

- Lighting designs and backlighting

- Capacitive and haptic PolyTC® sensors can be integrated

- 3D design with hologram effect

- Significantly shorter cycle times save energy

- Process suitable for series production