IMD UNIFY

Individualization for series production or unique items

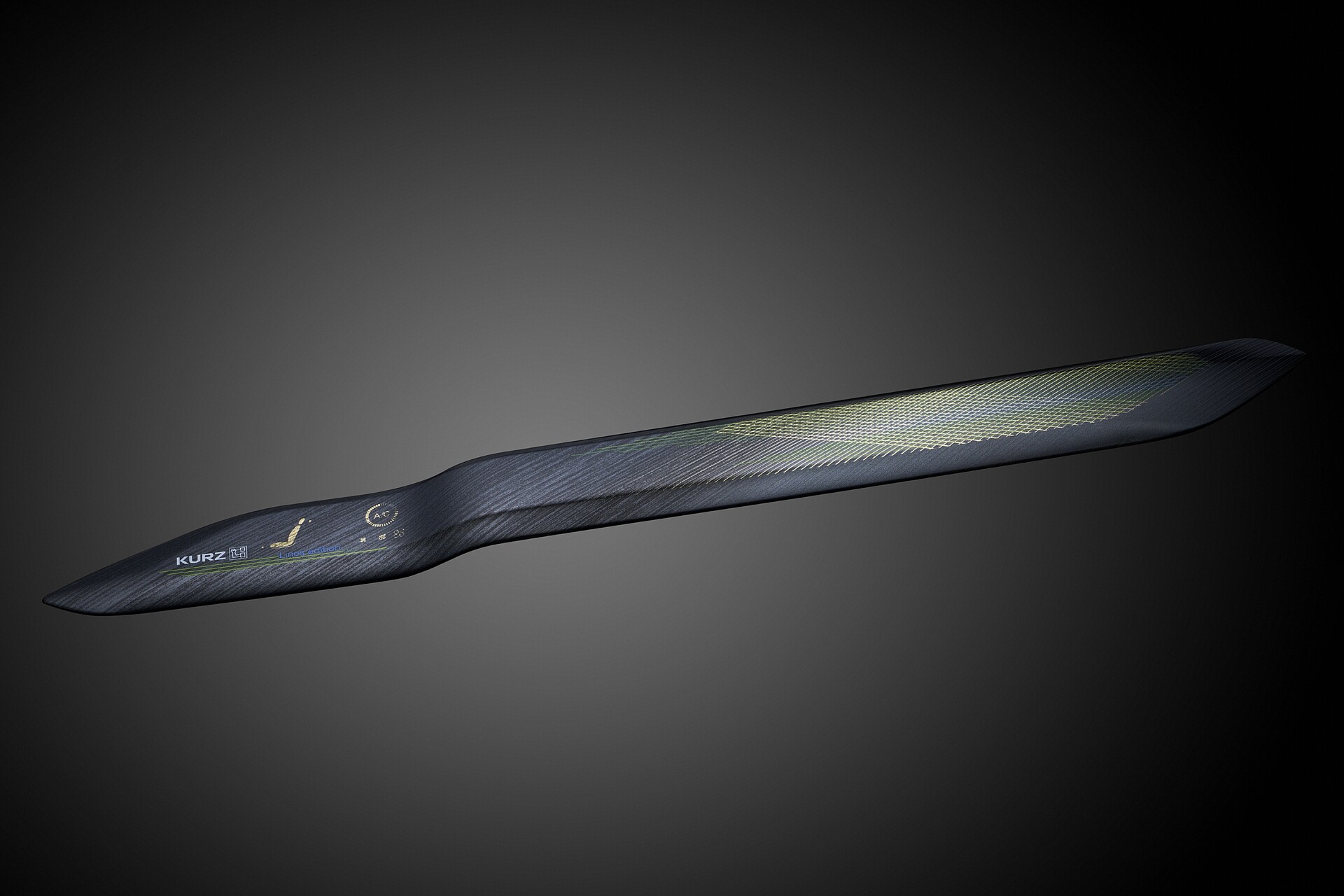

With IMD UNIFY, industrial companies can also economically implement individual products for their customers. Components are produced in series using the cost-efficient IMD process and then customized by means of digital printing. In this way, special editions, short-lived trends, and even very special requests can be efficiently implemented. Backlighting and touch functionality transform any interior surface into an intelligent interface for the driver.

- Components are decorated in the desired look during the injection molding stage using the economical IMD process

- In the second step, the component is customized through digital printing. This process makes it easy and efficient to implement special editions and personalized interiors. IMD UNIFY is the solution for all providers who want to offer their customers unique products in series

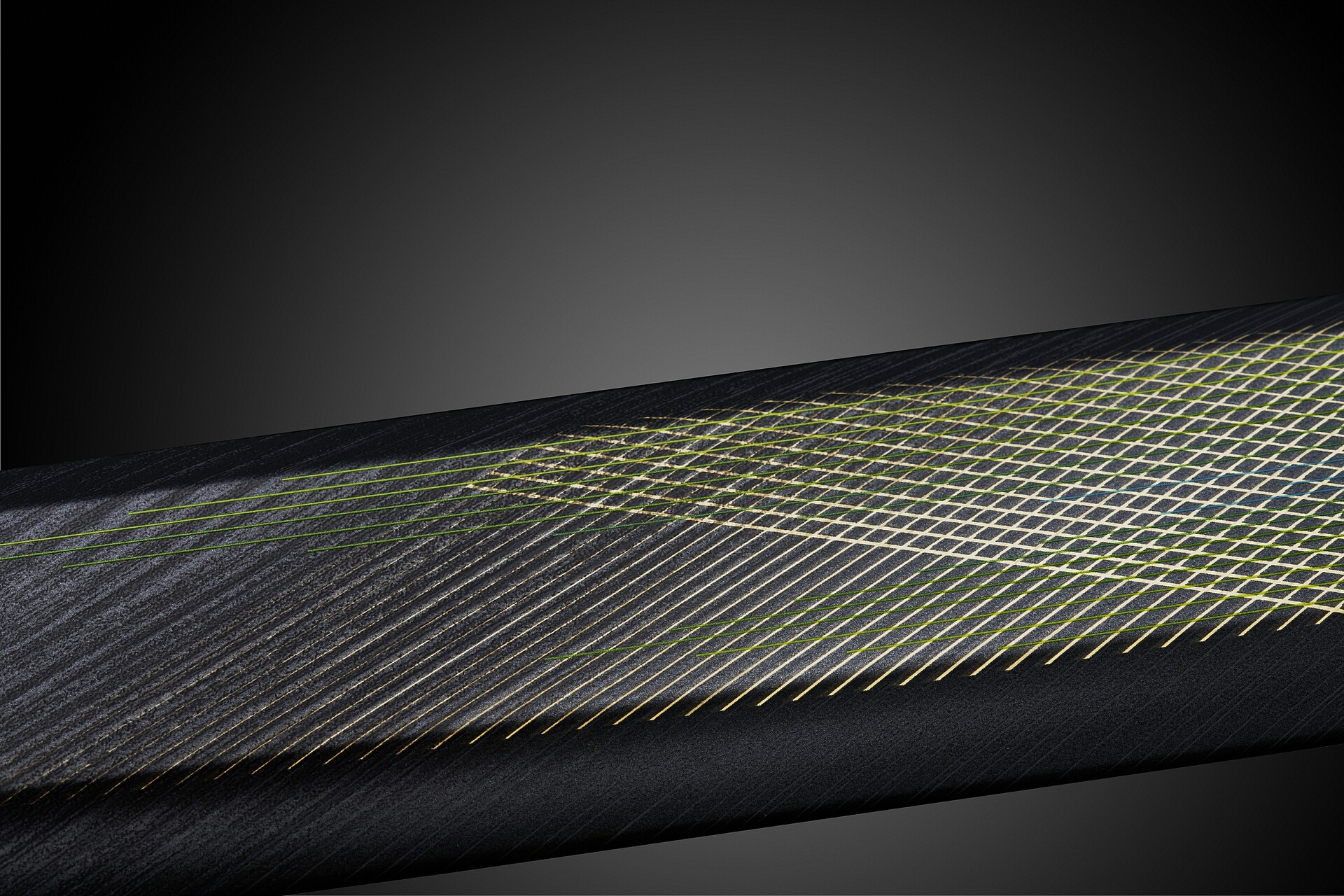

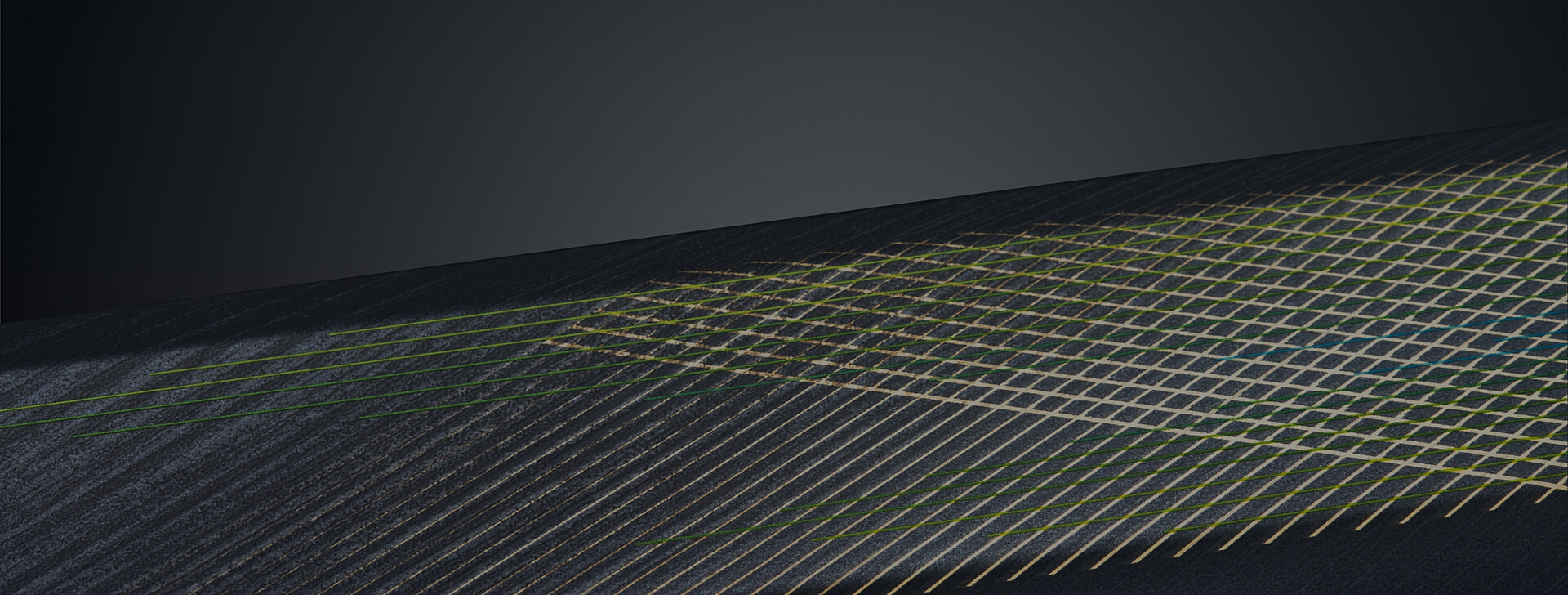

- Any conceivable look as well as backlighting effects, touch operation, innovative light design, and even haptic effects are possible. IMD UNIFY enables the perfect symbiosis of series advantage and individualization via direct digital overprinting

The advantages of customization with IMD UNIFY:

- Rapid manufacturing: serially produced components can be customized down to a quantity of 1

- Fast response to trends and special requests possible

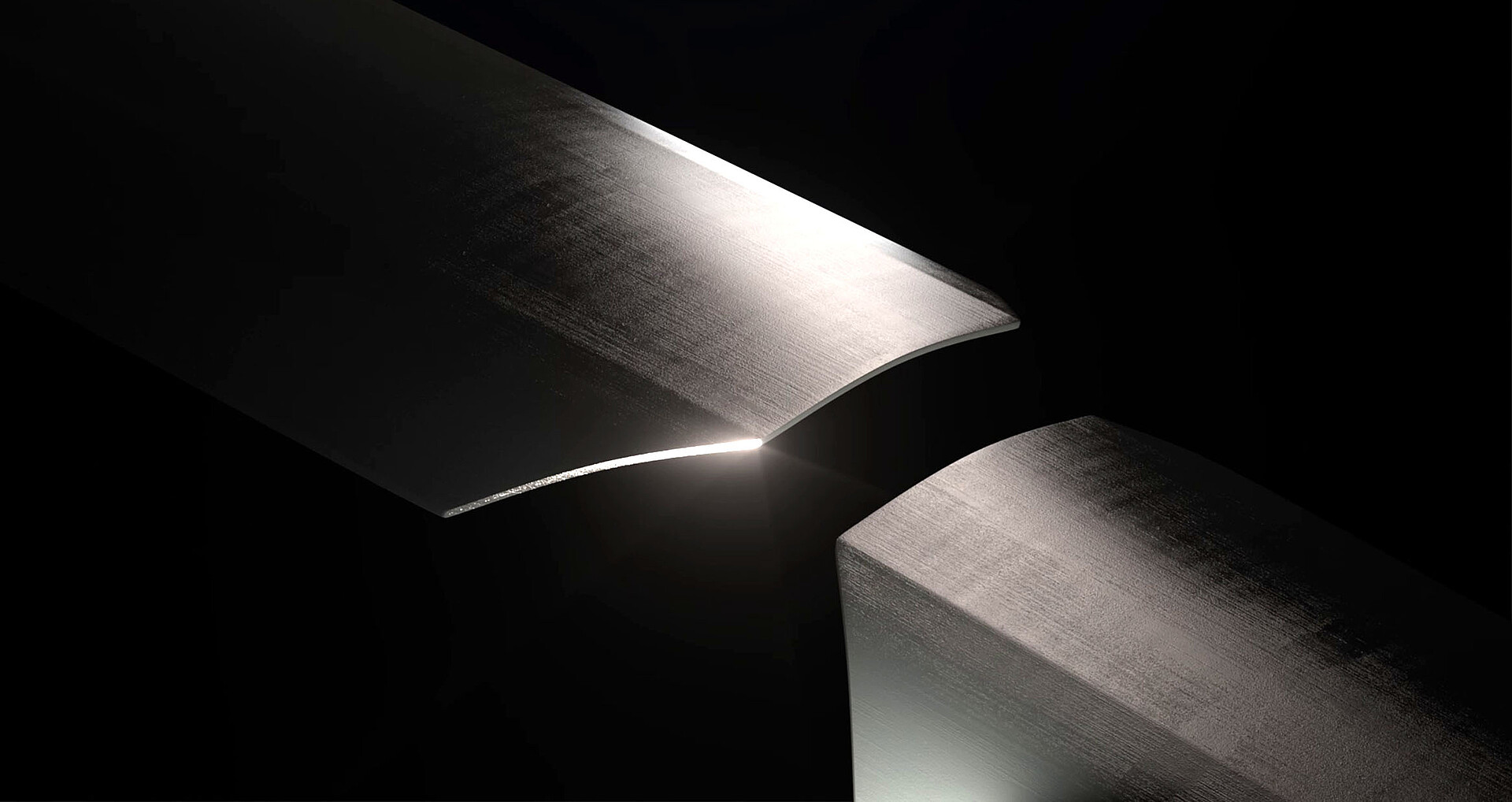

- Even extremely shaped components can be decorated

- Incredible design and customization freedom

- Shy tech designs with backlighting and ambient light possible

- Haptic designs are also possible

- Efficient and sustainable process, as resources are conserved and material is saved

- Can be used for recyclates

- Decoration does not affect the recyclability of the components