3K IMD Process

Production-ready technology with maximum efficiency

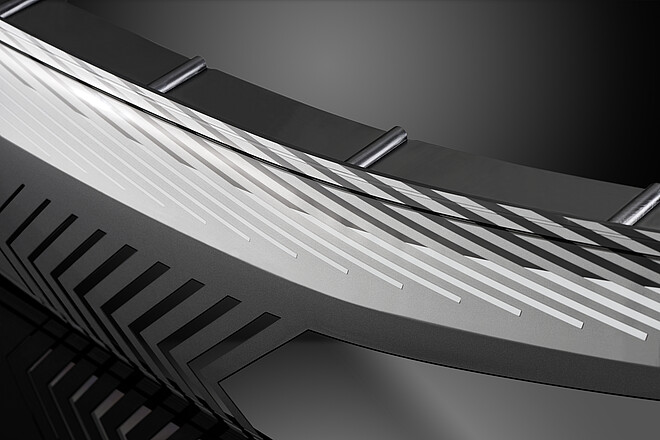

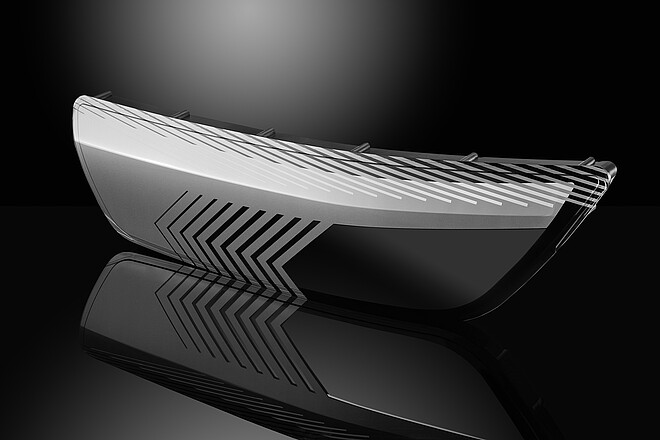

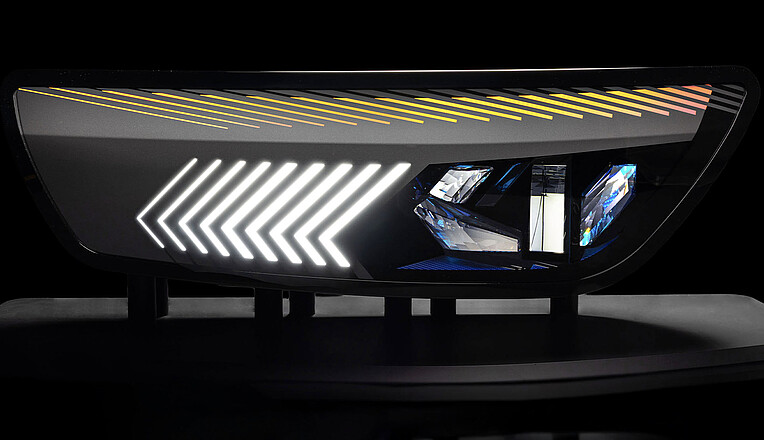

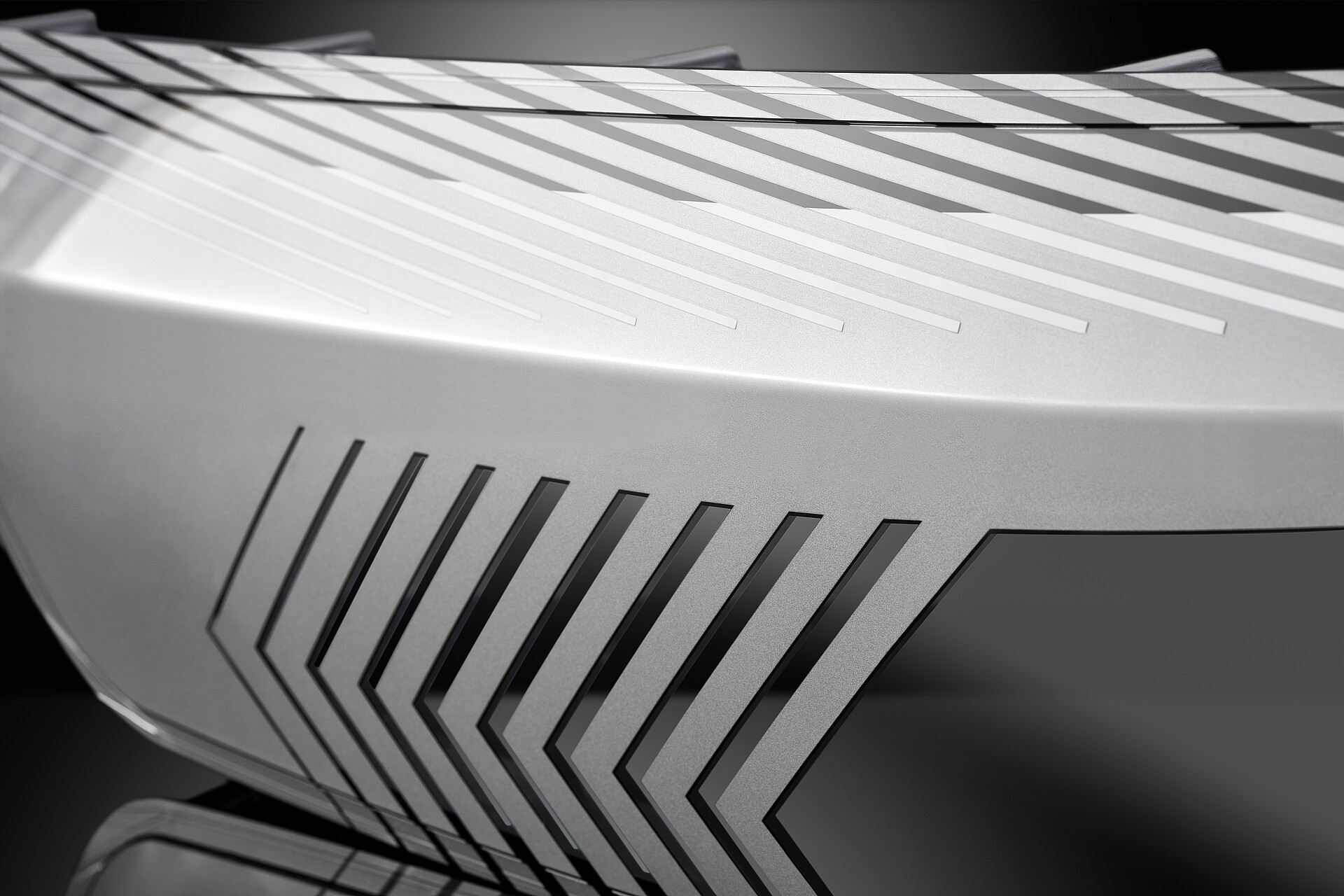

Is it possible to produce, decorate, and apply a protective coating to automotive components made of three different plastics and measuring up to two meters in a single process step? KURZ's innovative 3K IMD process makes it possible - with an optimized cycle time of less than two minutes. The energy- and cost-efficient technology can also be integrated into existing production lines and can contribute to a significant improvement in the CO2 balance compared to conventional processes. This allows the production of highly integrated components that combine design, light, and function - such as innovative headlights and other components for the design of the vehicle front, which are perfectly tailored to the requirements of e-mobility and autonomous driving.

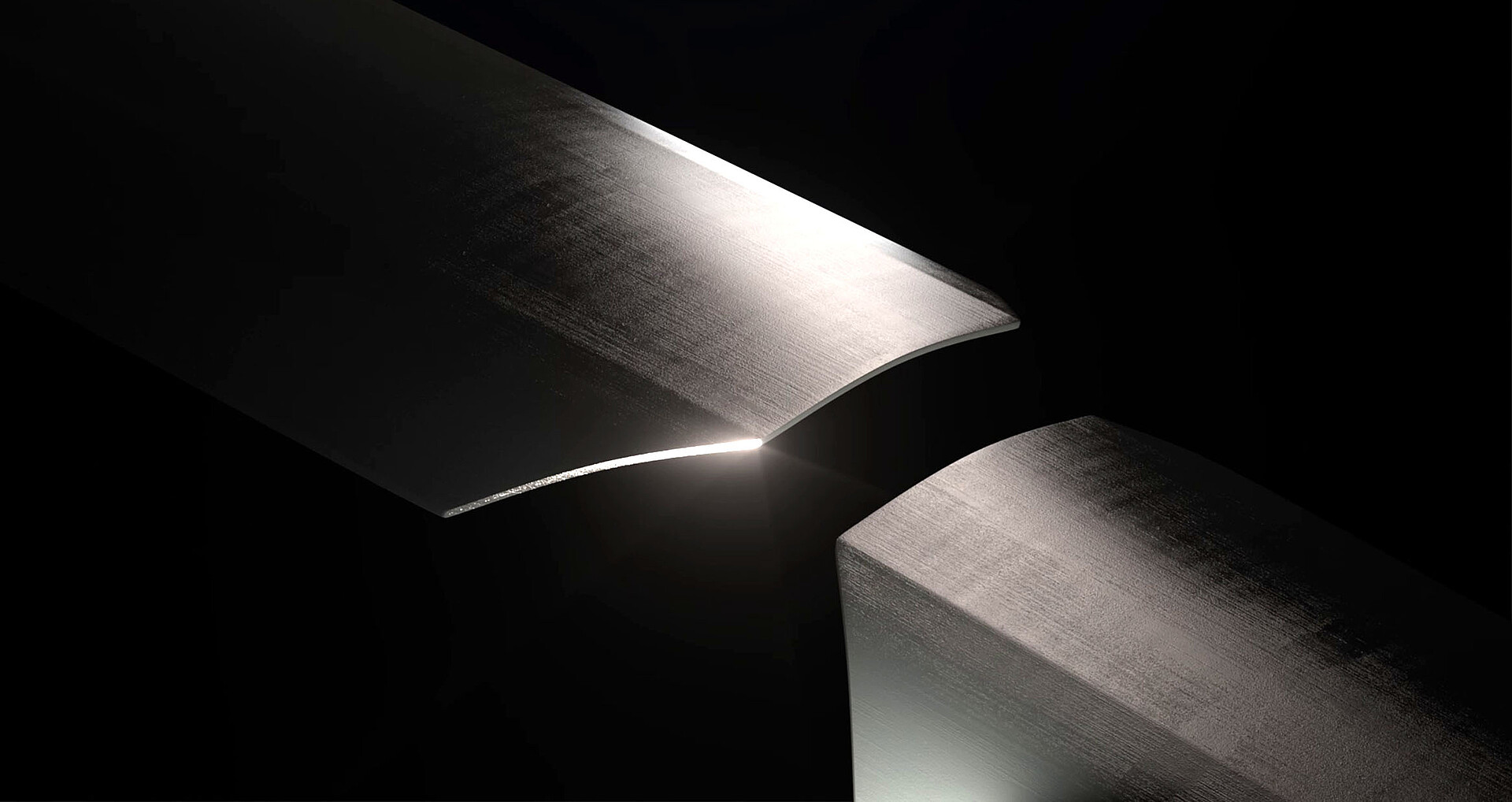

Form, design, and PUR protective coating in a single process step

With the 3K IMD process, we are introducing a groundbreaking innovation: In this highly efficient process, all steps – injection molding, deep drawing, and decoration – are carried out directly in one system. Three different plastic components are joined in a single process. Thanks to the IMD VARIOFORM® sheet-to-sheet technology with an innovative clamping frame system, combined in a 2K indexing machine with a PUR Colorform system, there is no need for upstream thermoforming – in line with lean, energy-efficient production.

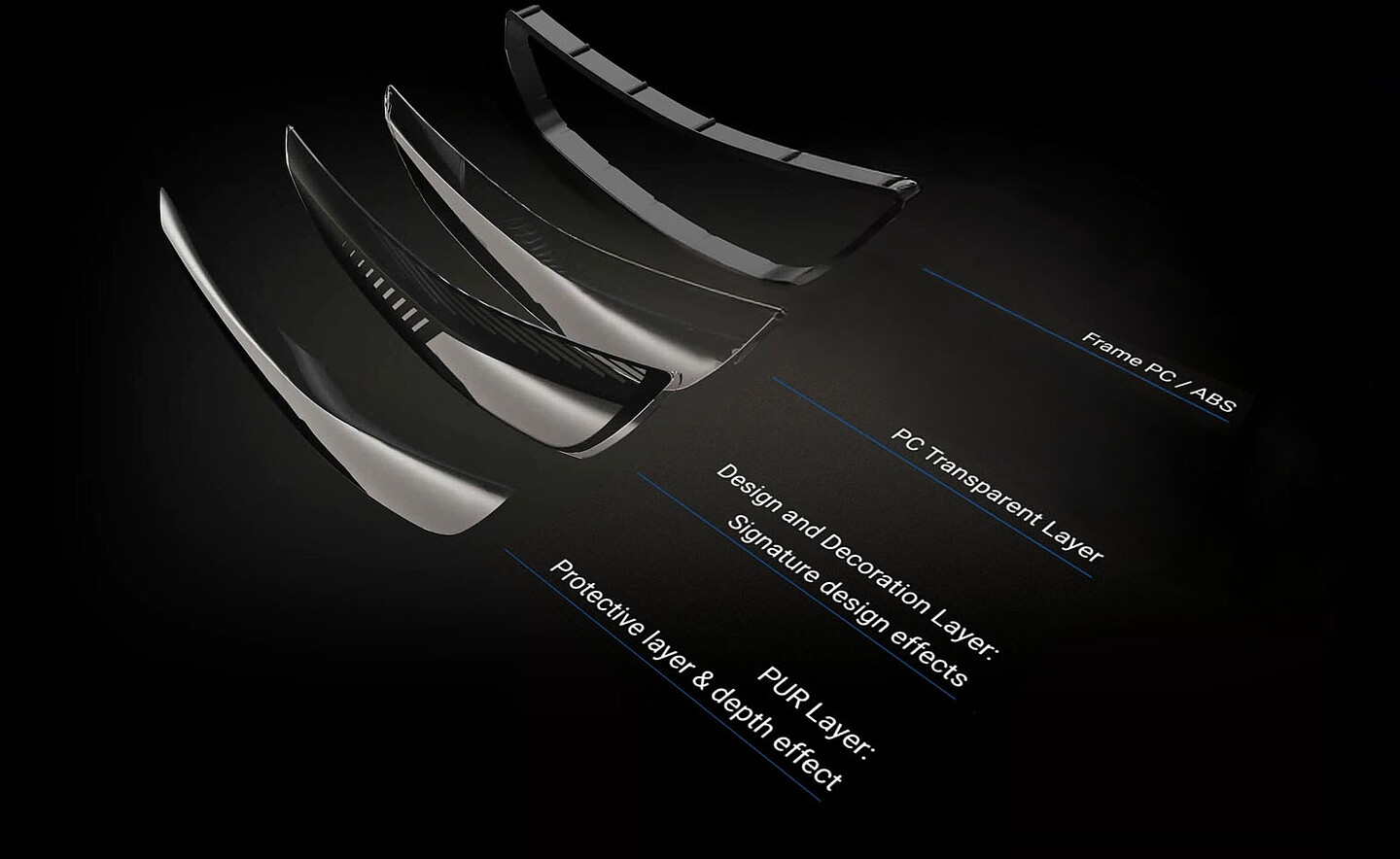

- First, a thermoplastic sheet is picked up by robotic arms and inserted into the mold. It is then shaped into the desired form using heat and vacuum pressure.

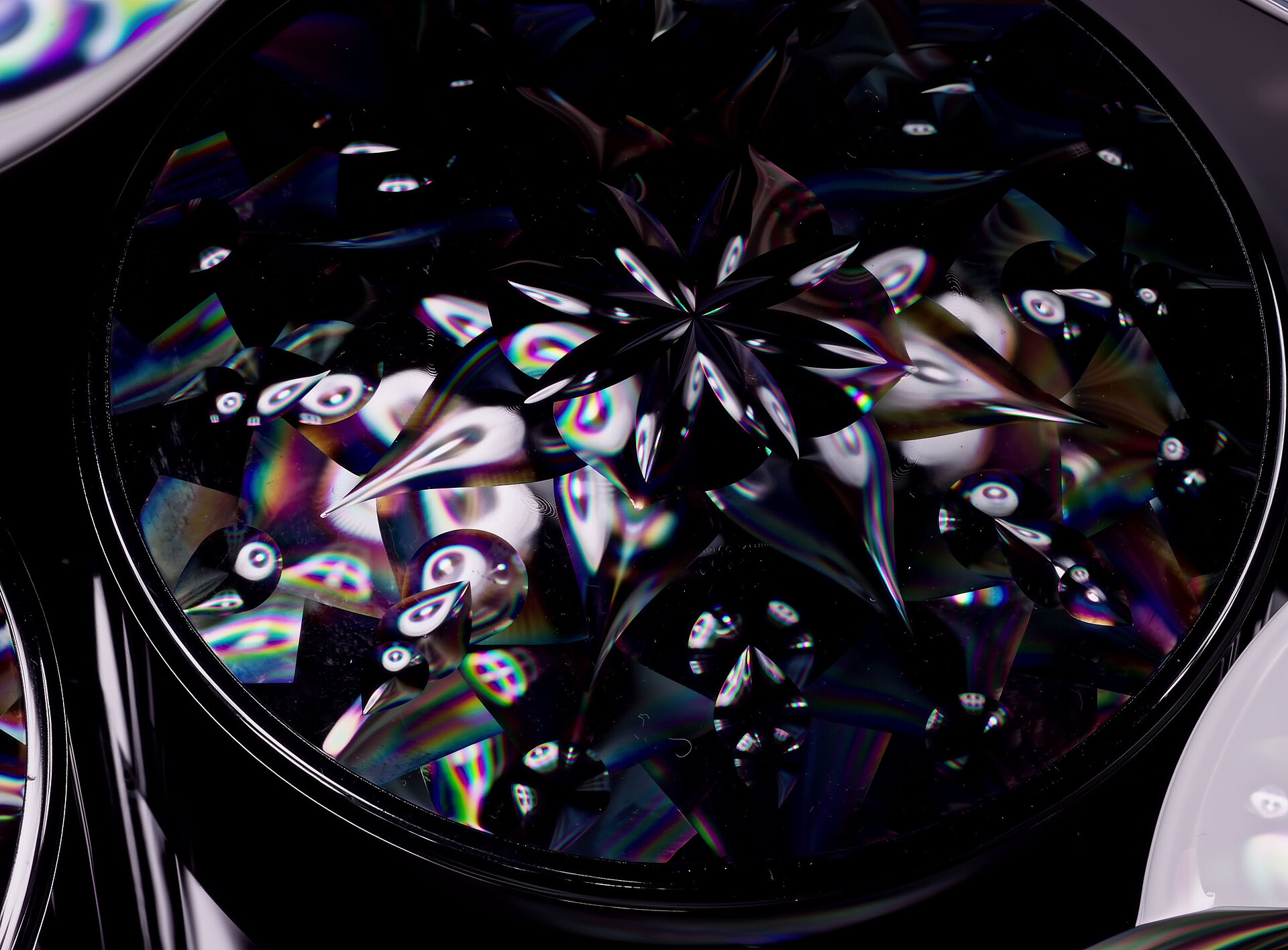

- Transparent PC is applied to the formed sheet using injection molding technology. This layer enables the optical functionality later on.

- Once this step is complete, the middle mold halves are rotated 180°. Thanks to this unique feature, which is made possible by the next generation scalable turning plate technology from KURZ subsidiary SCHÖFER, the process is ideal for manufacturing large components from a 3K material mix.

- In the next step, a stabilizing frame made of opaque ABS/PC is injection molded, followed by another rotation of the inner mold halves.

- Finally, the component is flooded with polyurethane (PUR), which provides it with a protective layer – for added durability, scratch resistance, and longevity. Bio-based PUR can be used on request.

The advantages at a glance

- Production-ready technology

- High time, energy, and cost efficiency thanks to one-stop production

- Injection molding, deep drawing, and decoration in a single process step

- Optimized cycle time of less than 2 minutes

- Optimized CO2 footprint thanks to energy-efficient technology

- Seamless process integration into existing machine lines possible

- Ideal for the production of large-sized components

- Integration of invisible heating elements and radar sensors possible

- Use of recycled materials and bio-based material components possible