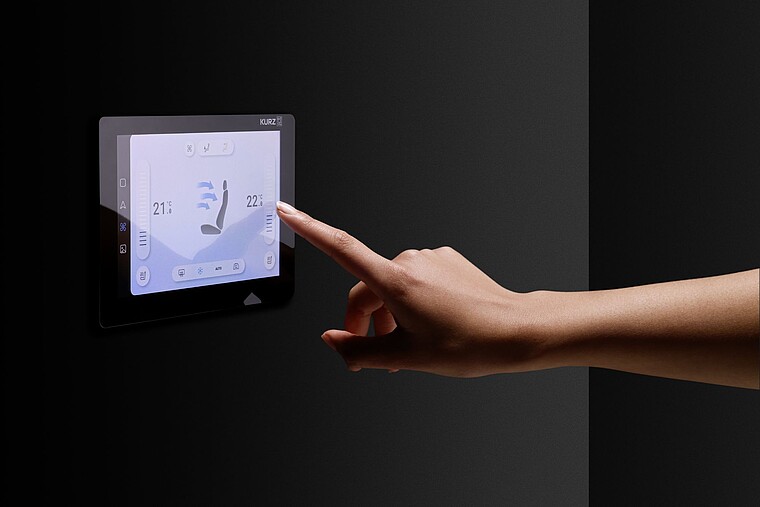

In-Mold Electronics (IME)

Forming, decoration, and sensor integration in one

For producers and suppliers, efficient and sustainable processes, high flexibility, and the ability to implement the trends of tomorrow today are the most important factors. With In-Mold Electronics, KURZ has developed a technology that optimally supports these requirements. Tier 1 and 2 suppliers benefit equally from efficiency and flexibility: They can decorate their components and at the same time integrate state-of-the-art functionality in a single production process. This shortens their value chain and saves energy. Strengthen your market position and rely on solutions from a single source - from the concept to the machine, and from the tool all the way to process integration!

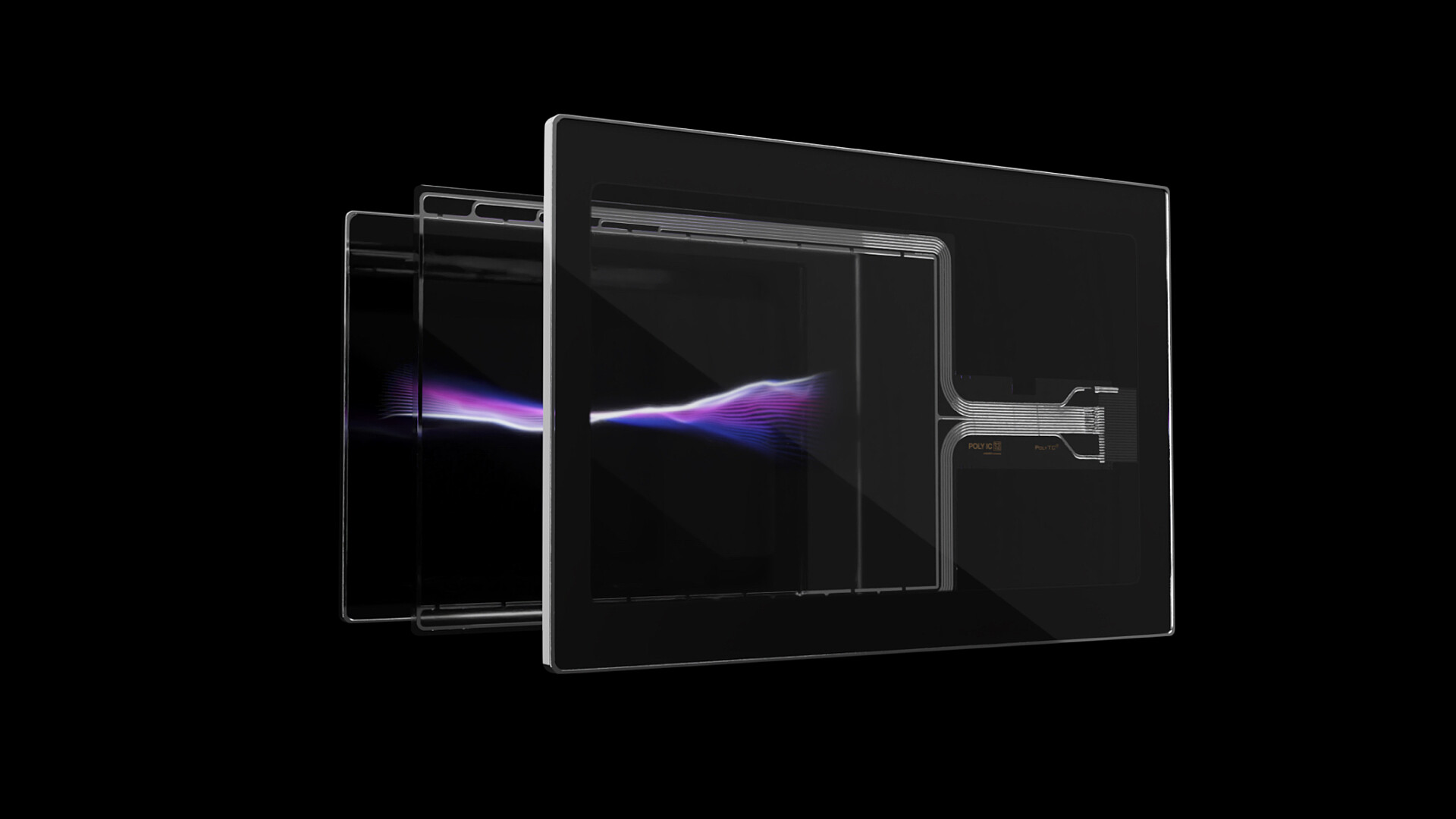

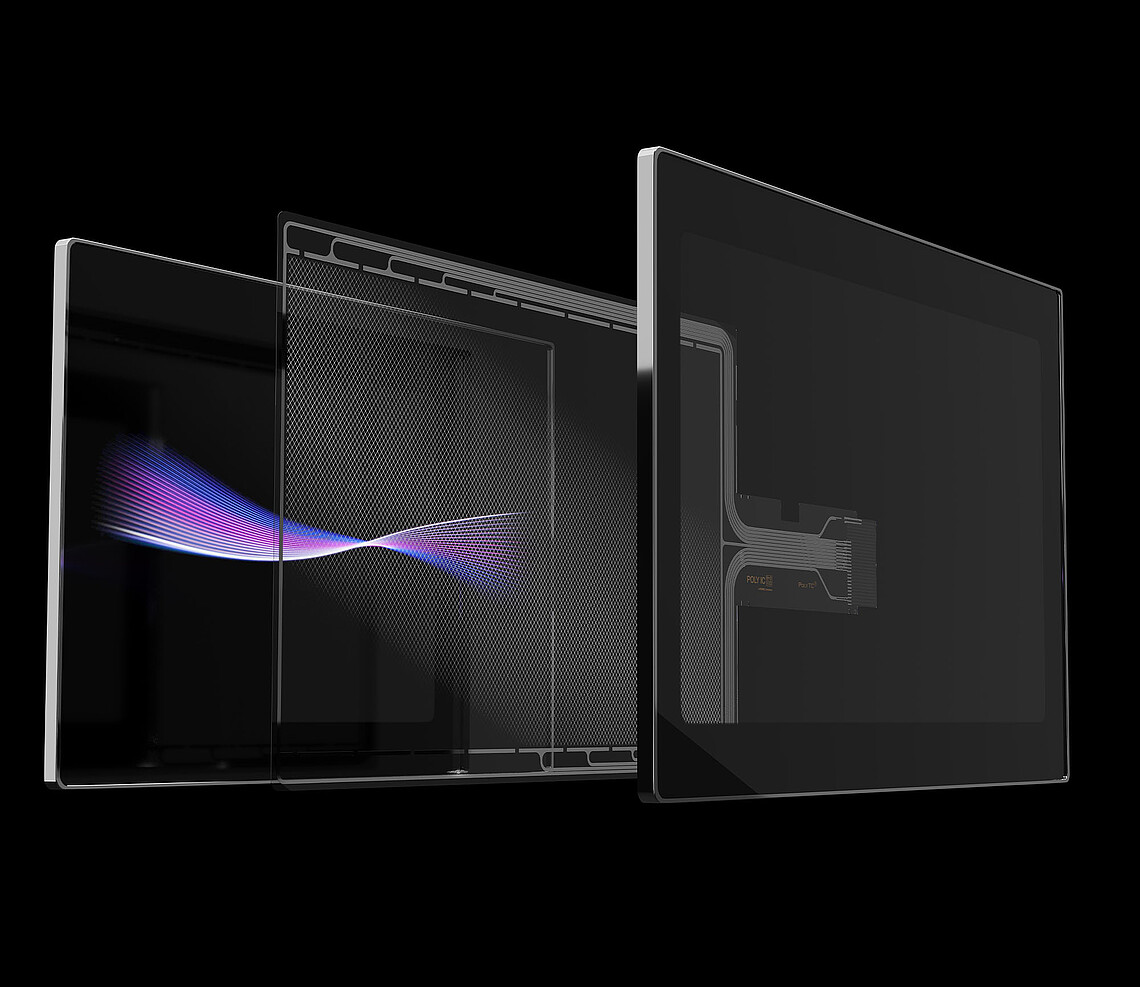

On one side of the tool, the decorative coating and design for the front side of the control panel is positioned in the front cavity.

At the same time, the metal mesh label with PolyTC® sensors is inserted into the opposite cavity.

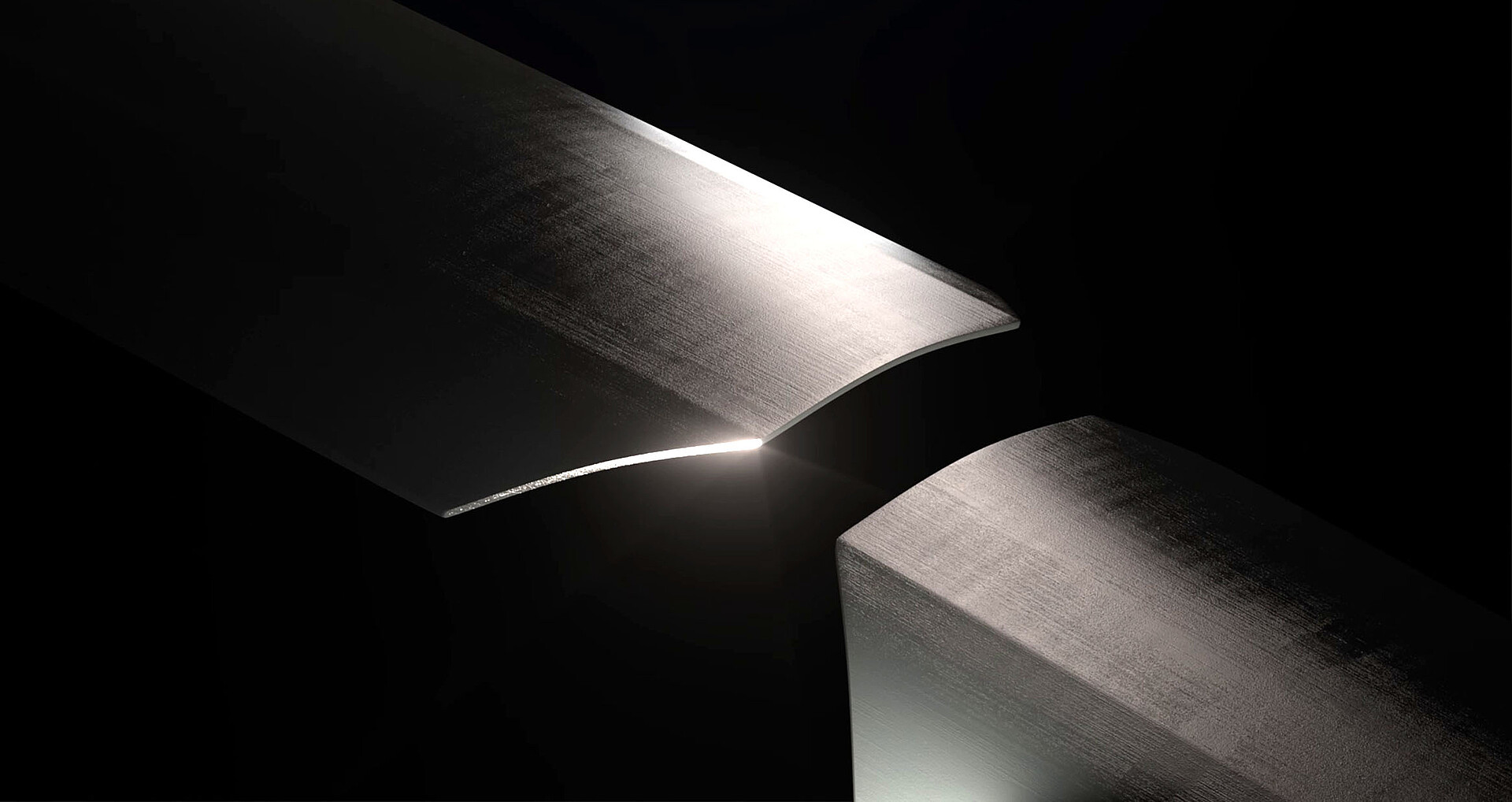

Then the tool closes.

Next, a plastic injection molding process controlled by precisely metered heat and exact pressure occurs, which completely molds the final component. In this process step, the decor is transferred firmly and in excellent visual quality to the front.

At the same time, the plastic and the transparent sensor substrate are fused on the rear side. To make this technical step possible with reliable functionality of the touch sensors, KURZ has developed a special formulation. This not only optimizes the stable connection of the materials, but also ensures that the sensors are permanently sealed, which is important for perfect functioning even in adverse environmental conditions.

When it comes to shaping your product batches, 2D to 3D are possible. Decorative coatings can also be applied to inserts. With this process, you also have the option to only perform the sensor integration and forego adding a design on the front.

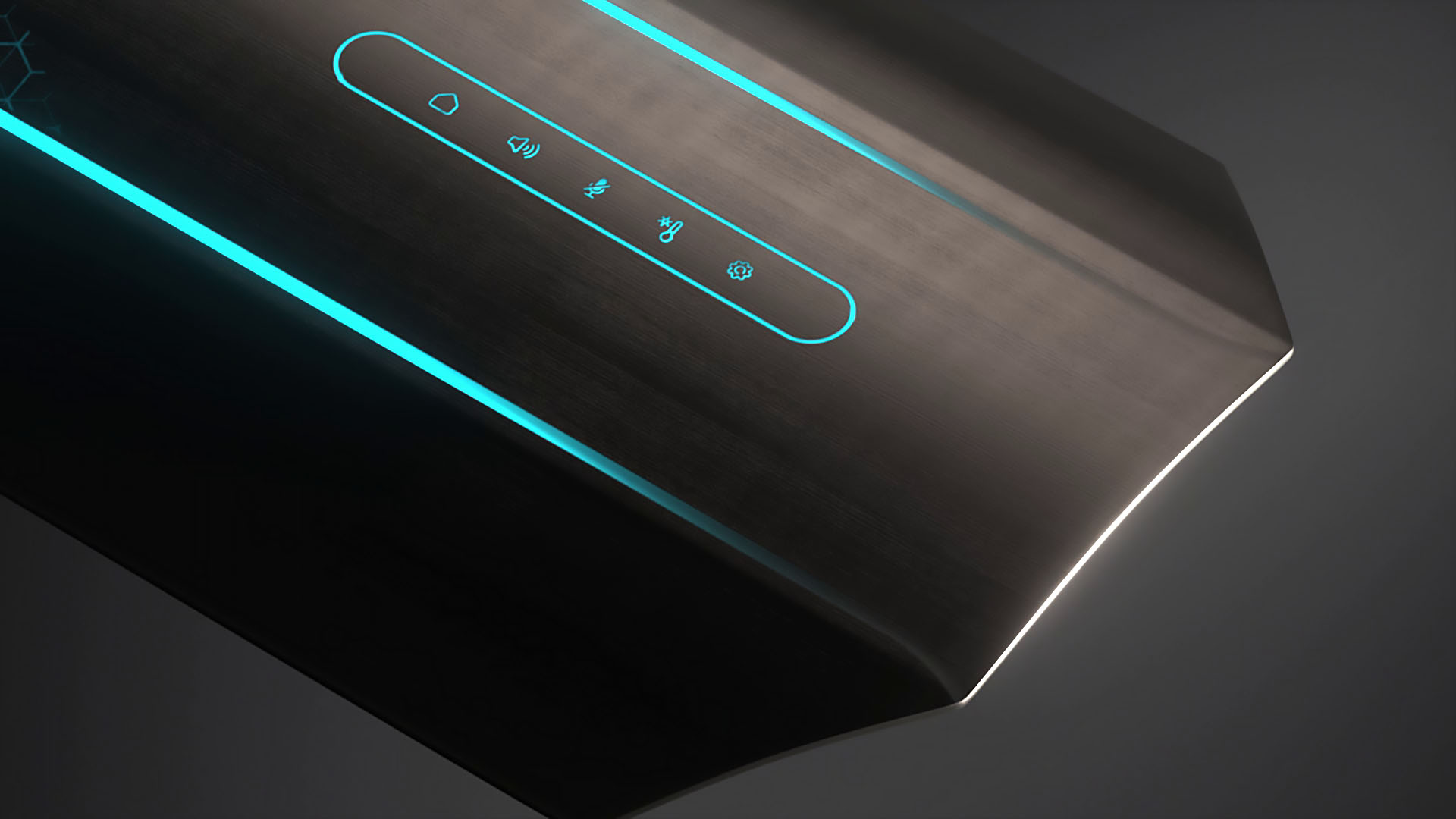

HMI Overhead Light Console

In one step, a functional rooftop component with integrated touch functionality and multifunctional control options is produced.

Efficient and sustainable

- Significant reduction of CO2 emissions is achieved through a highly efficient and series-ready one step production process.

- Dry decoration process, meaning that energy-intensive steps such as post-drying are omitted.

- Ultra-thin PolyTC® sensors remove the need for buttons and switches; they also reduce the weight of components.

- Can also be used to decorate recyclates.

- The recyclability of the components is not impaired by the surface finishing.

- Numerous surface decorations are possible: Backlighting, customer-specific requirements in terms of design and durability, soft-touch surfaces, or even real metallization.