Hot Stamping

Maximum precision for your plastic surfaces

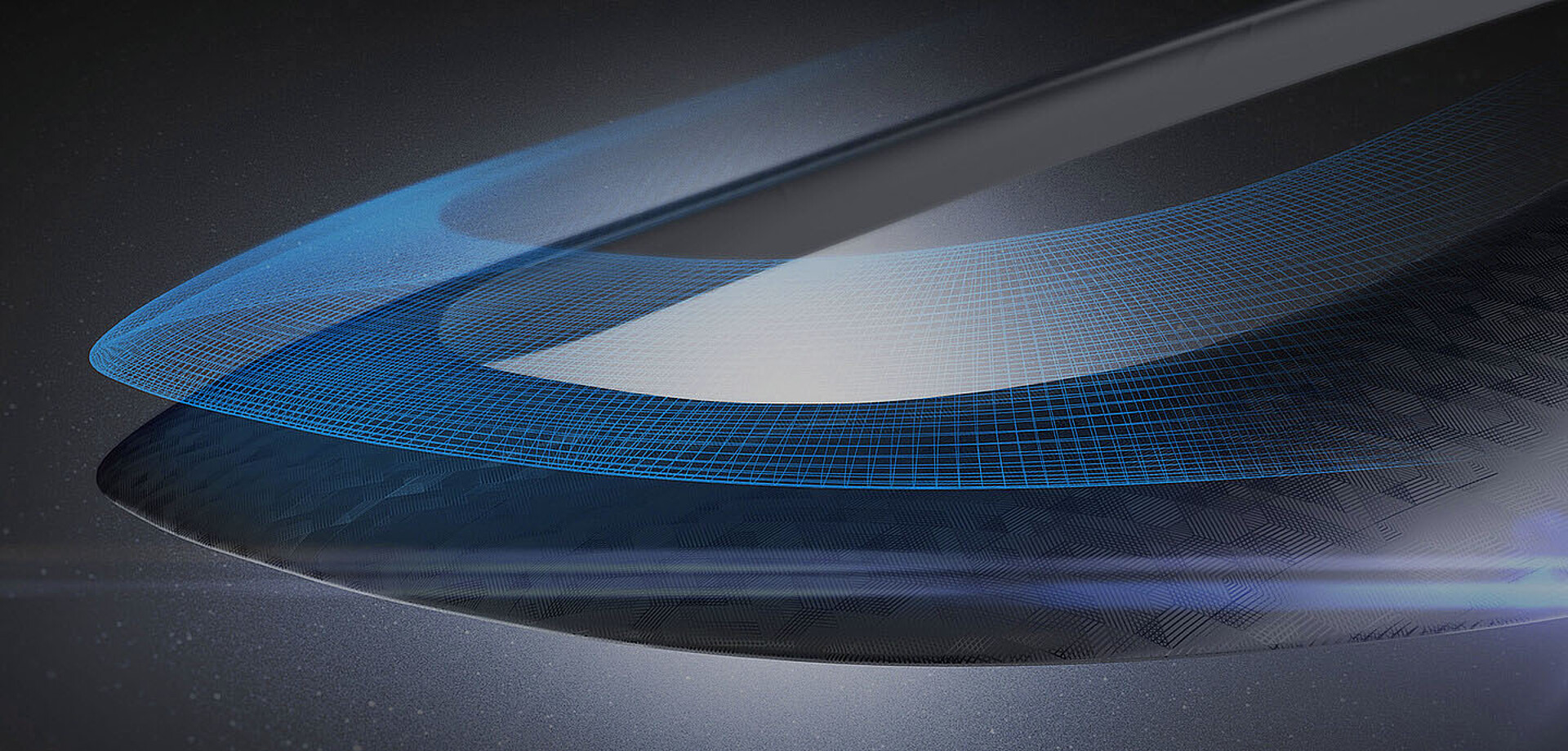

Maximum precision for your plastic surfaces: From color gradients to razor-sharp decors in the highest photo quality, you can put your stamp on your surfaces to promote your brand. You can refine all or part of your products in a single operation. Even sustainable chromium-based metallization is possible with this process. Benefit from maximum flexibility and precision. What’s more, our decorations don’t affect the recyclability of the surfaces.

Hot Stamping PERFORMANCE+

Hot Stamping PERFORMANCE+ is particularly suitable for decorating complex multidimensional geometries. A two-part mold is used in this process. While the components are inserted fully automatically into the lower part of the mold, the carrier film with the decoration, which is guided on a roll above the component, is drawn to the wall of the upper mold part by vacuum. The tool closes, pressing the coating onto the component with heat. The carrier material is then peeled off. Users benefit from high efficiency and lower energy consumption than with classic Hot Stamping, as PERFORMANCE+ eliminates the need to preheat the material.

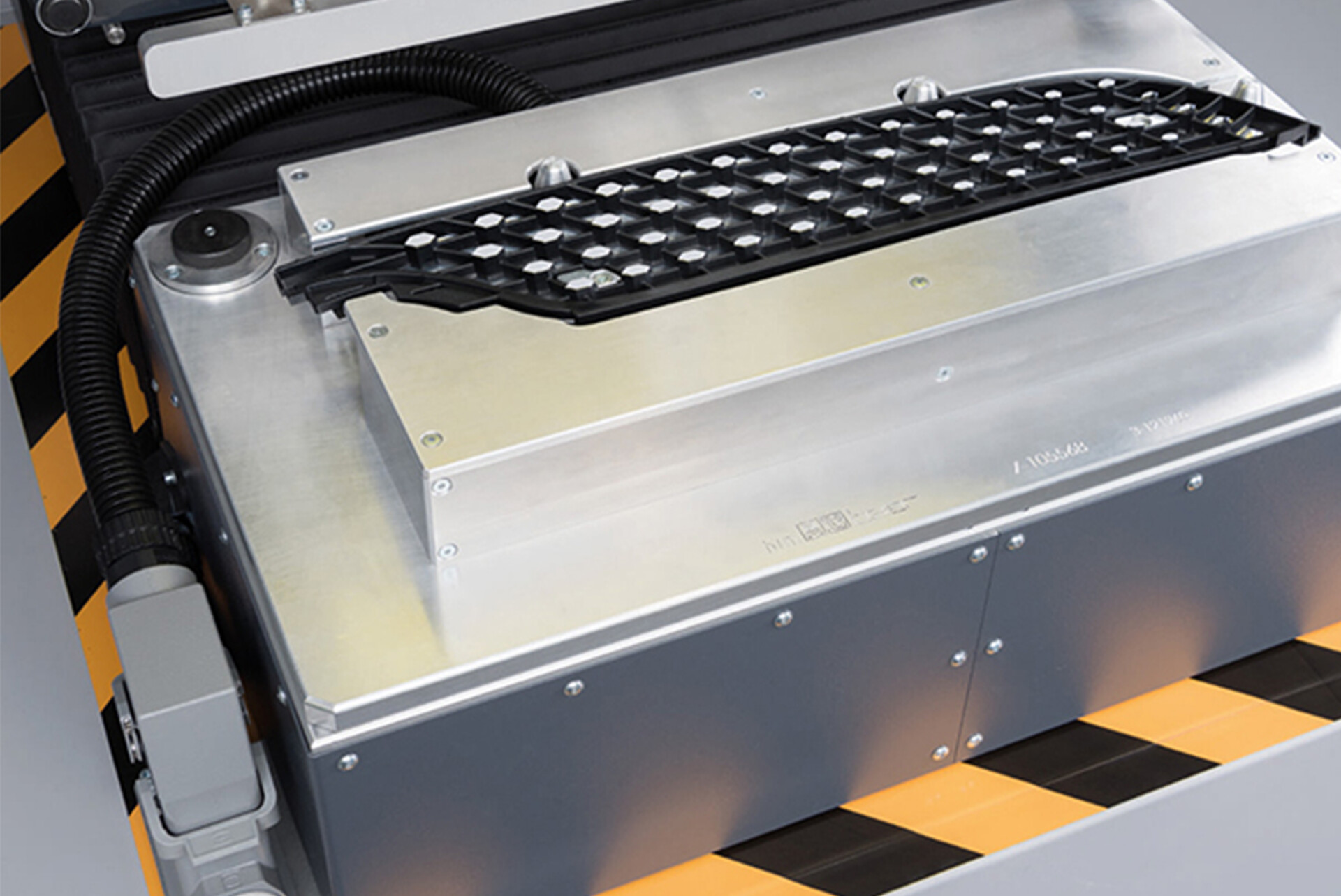

Vertical stamping

With vertical stamping, the decor is transferred to molded plastic parts via a heatable embossing stamp in short and fast upward and downward movements. For this purpose, part after part is pushed fully automatically under the rising and lowering moving embossing stamp. The shape of the stamp determines the form and appearance of the decoration. This method is particularly suitable for large-scale decoration and raised decorative structures.

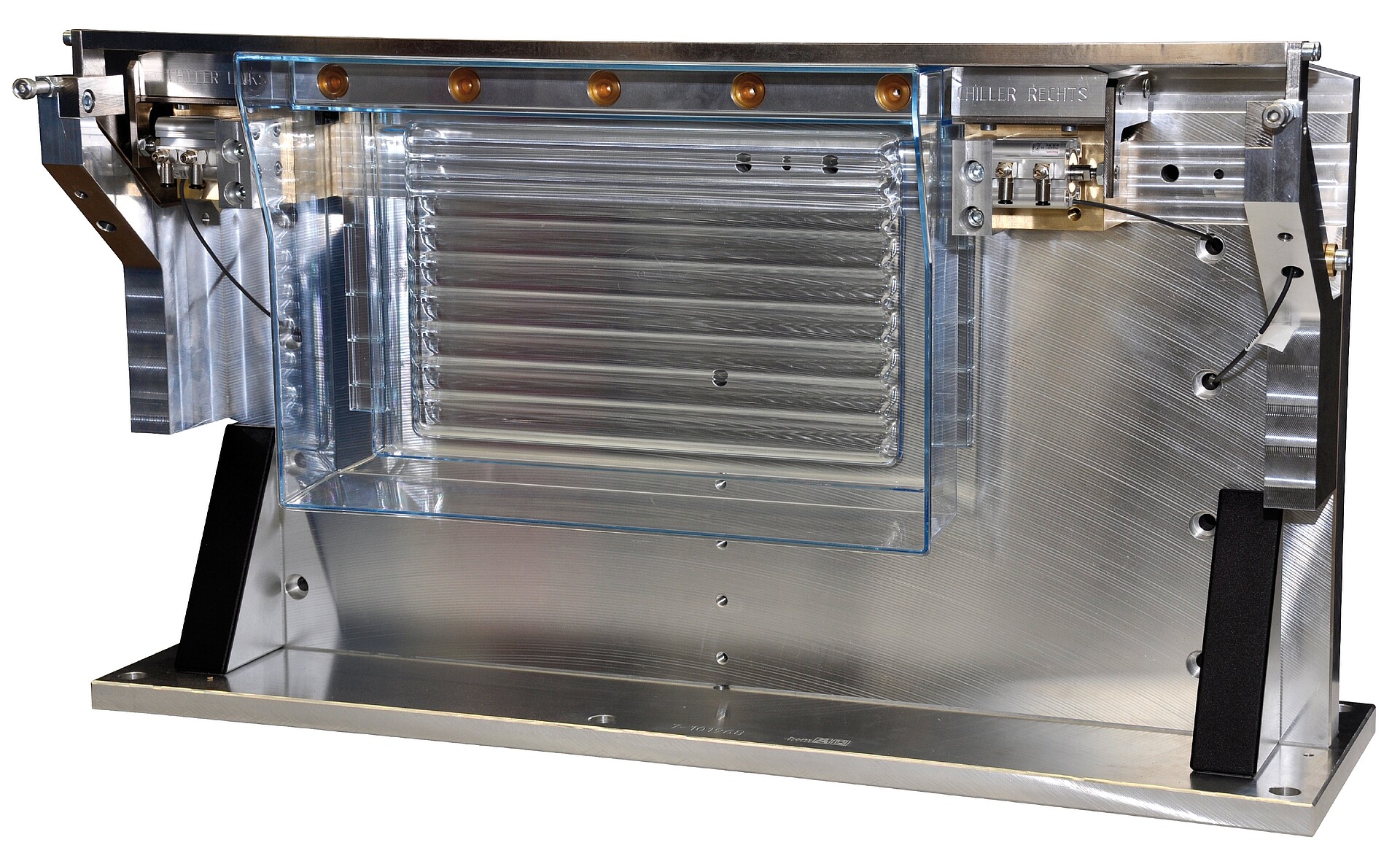

Roller embossing

During the roller embossing process, a conveyor belt transports the molded plastic parts along under the heatable embossing wheel. At the same time, the material with the wafer-thin coating in the desired decor runs over the embossing wheel. The motifs are transferred piece by piece to the plastic by the continuous rolling movement and the applied pressure. This technical process can be used, in particular, for large areas, profiles, and sprayed contours or areas.

Hot Stamping expertise from a single source

Our range includes everything OEMs and suppliers want for their automotive surfaces: Glossy and matte designs, SLM foils, in BRUSHED look or glossy for fans of a metallic look and feel. Because we also implement haptic designs with our finishings. Thinner than a human hair, they are recyclable.

The KURZ Group not only offers the right decorative layers, but also the right machines for the application. With the KURZ subsidiaries BAIER (machines) and Hinderer + Mühlich (stamping tools and jigs), you can add the desired processes to your production line efficiently and flexibly. KURZ supports you along the entire value chain.