RIM Design

A design revolution for wheels

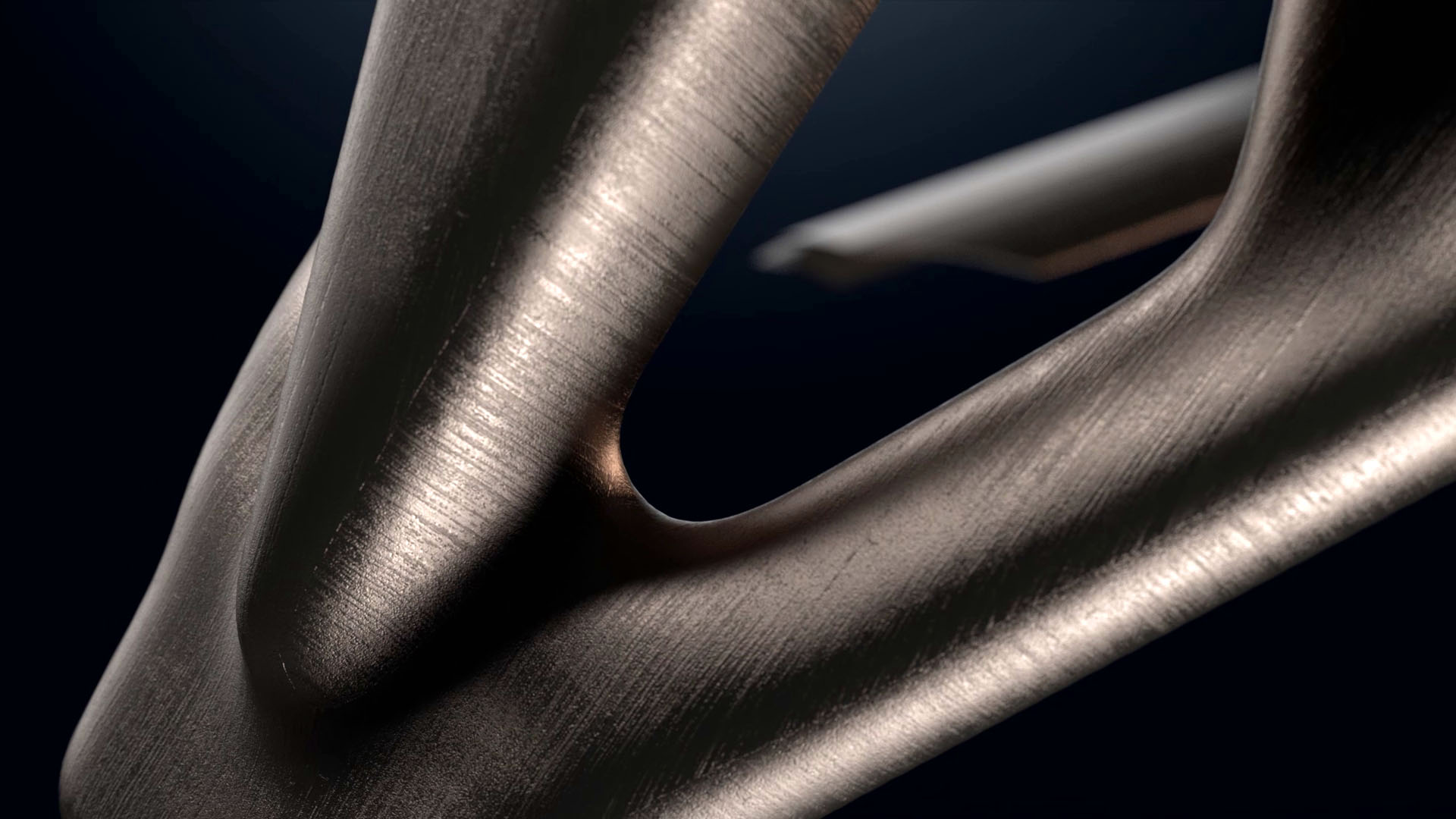

Car wheels? Design objects. Whether steel or aluminum: Rims offer a previously unheard-of opportunity to customize the exterior. Together with industry experts, KURZ develops solutions that make rims a unique eye-catcher on every vehicle: With our Advanced Wheel Decoration Concept, you can benefit from unprecedented design options that can give your brand a decisive competitive edge. Every wheel is a statement – thanks to hot stamping. Our patented process for thin-film decoration of complex 3D rim components offers an additional plus in sustainability: The production-ready RIM design is also suitable for the use of recycled materials.

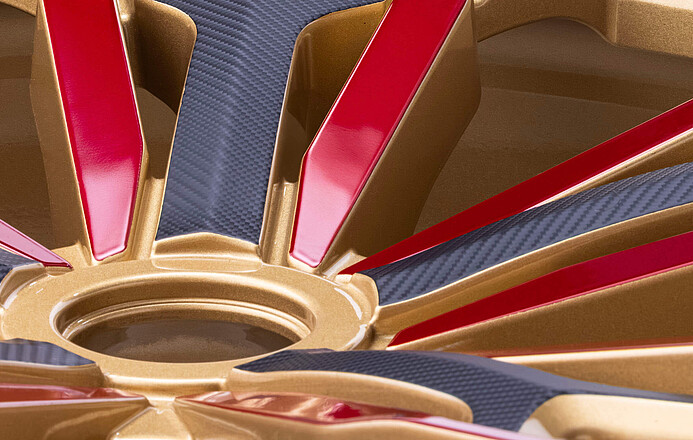

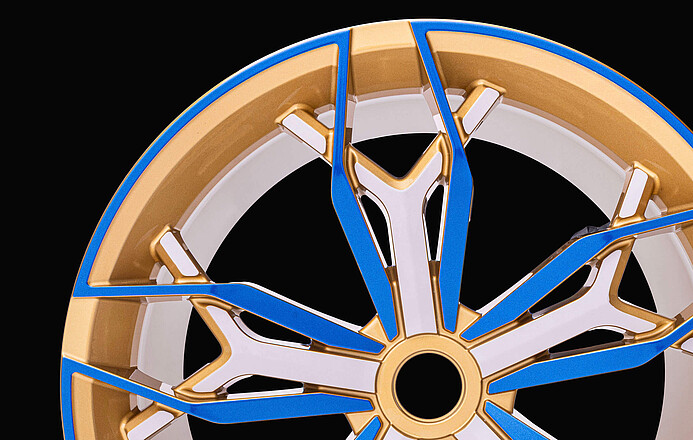

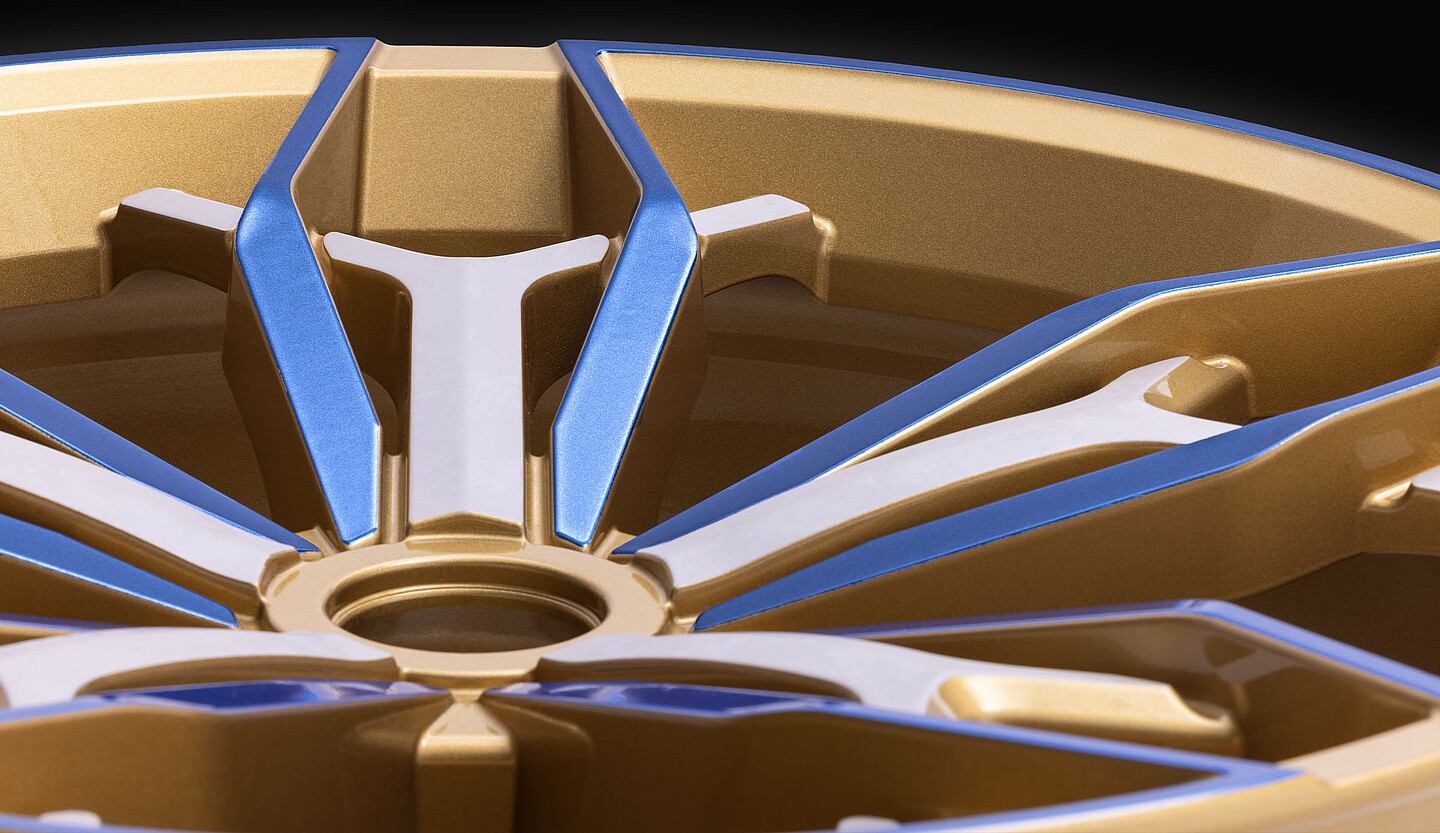

Hot stamping on aluminum rims

Getting the design revolution rolling: hot stamping is used to directly and efficiently finish RONAL aluminum wheels. Without additional work steps such as electroplating; metallic color gradients, intricate color accents, or impressive hologram effects are created and set new design standards – tailored to customer specific design elements and color codes.

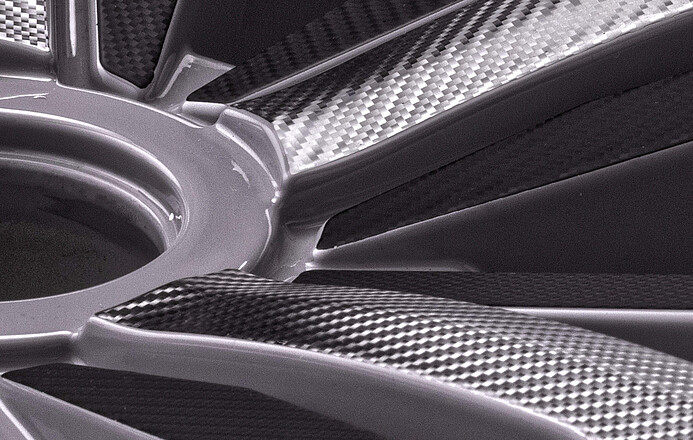

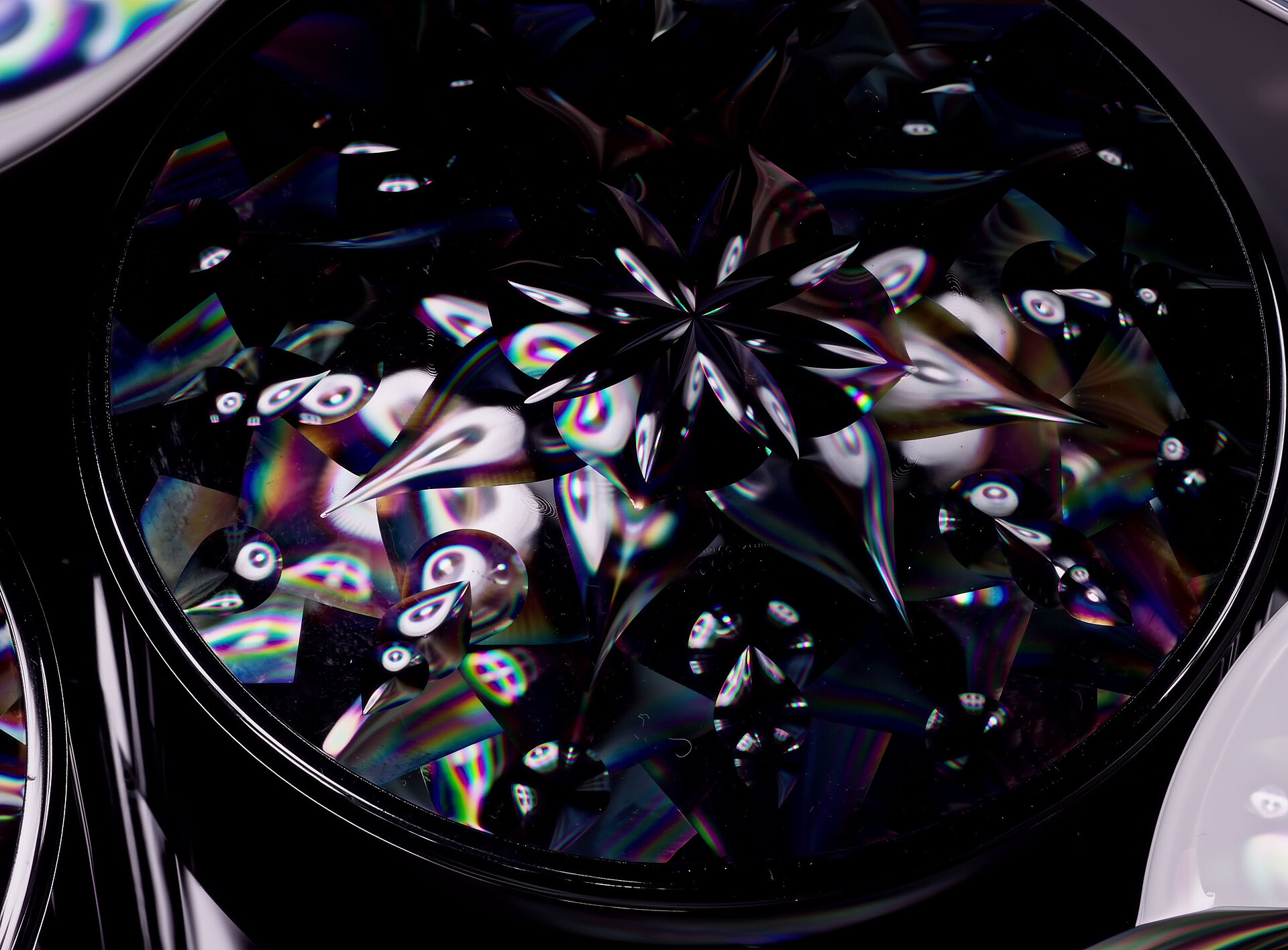

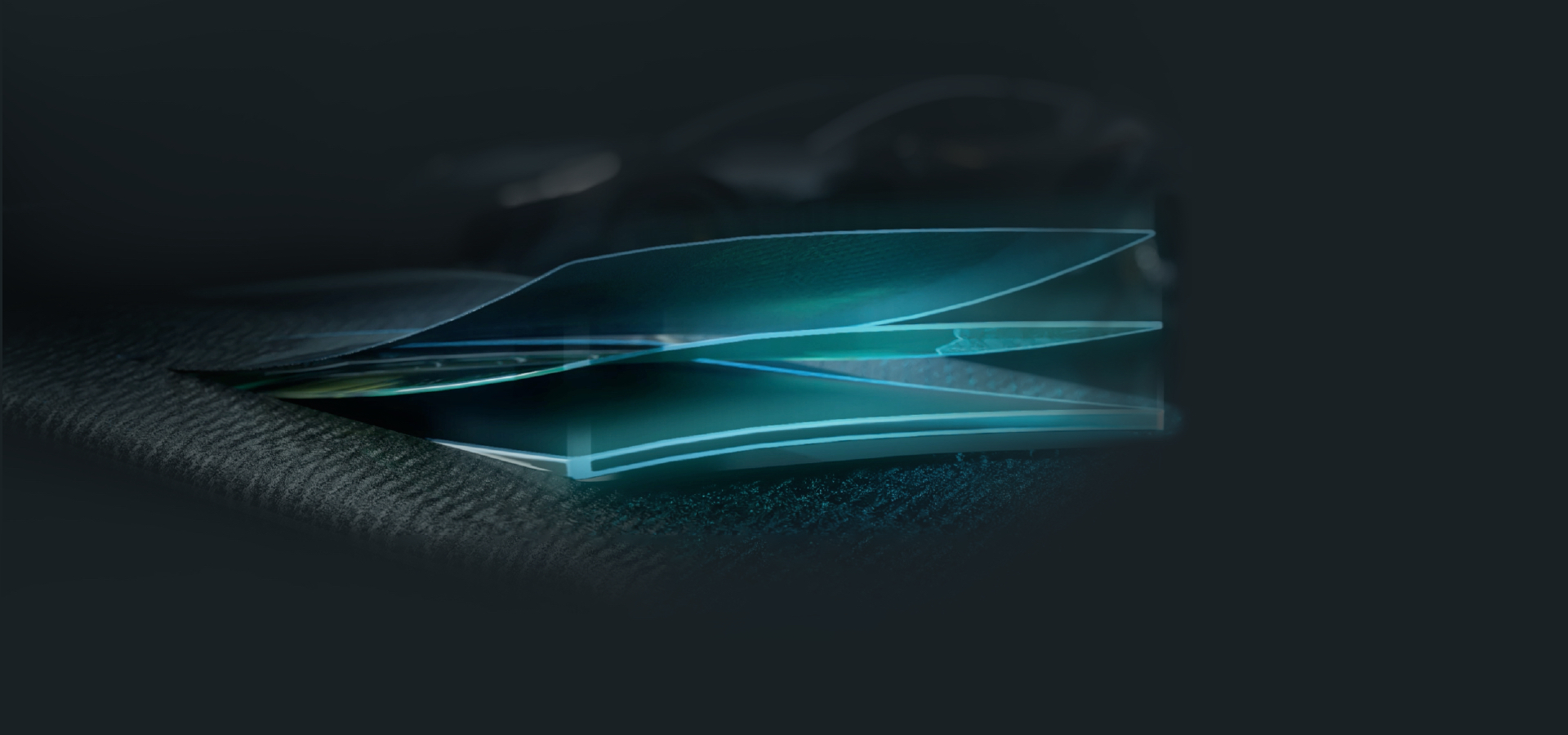

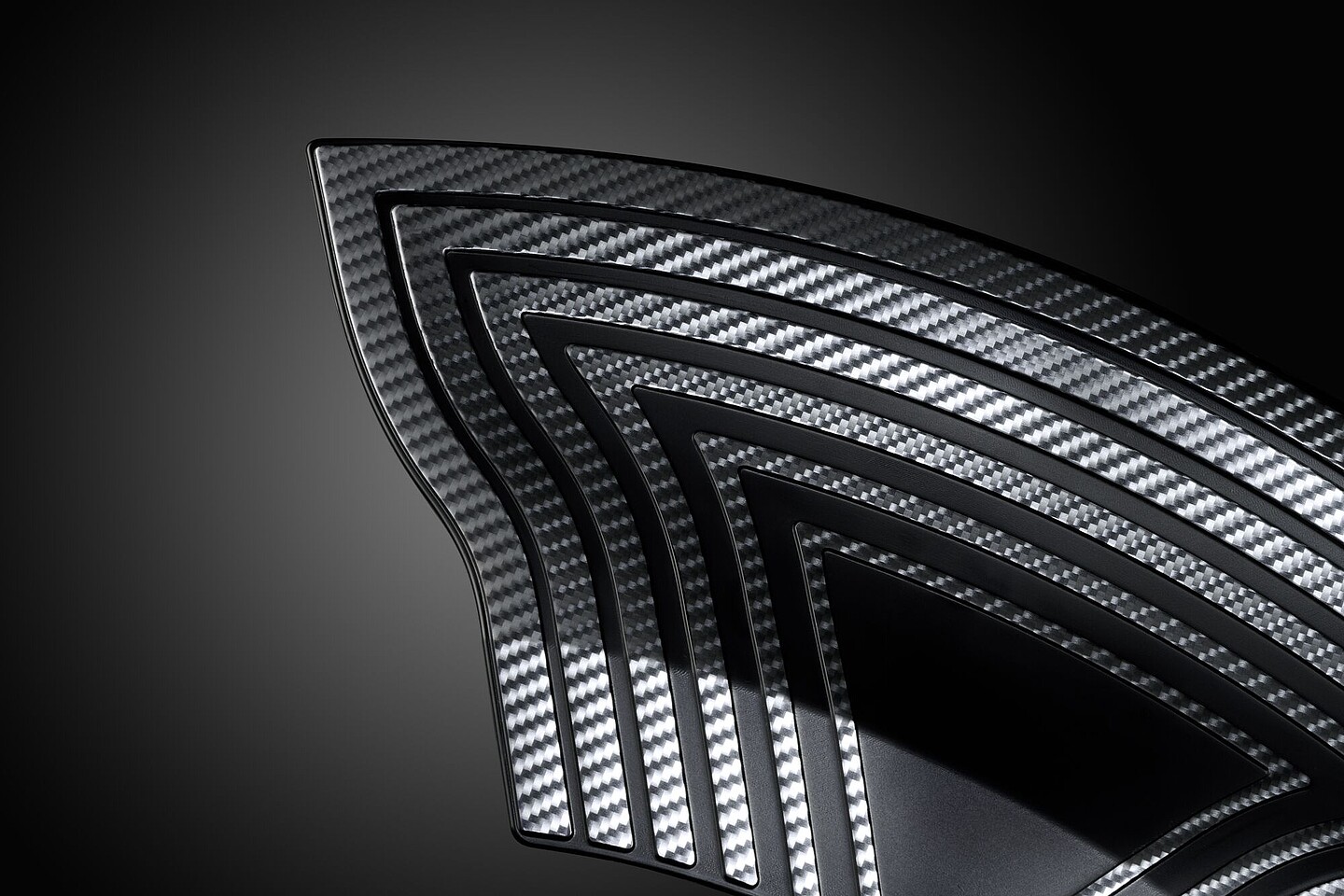

Precision down to the smallest detail: Rim inserts with holographic carbon design

Holographic carbon design is the perfect complement to the wheel design of the future. New light effects and reflections are created, especially in motion. What’s more, the inserts reduce air resistance, thus increasing the range of electric vehicles and lowering the noise level when driving. The production-ready decoration process is also suitable for the use of recycled materials.

Rims of the future

- Partial or full decoration for rims and inserts

- Unique decoration for wheels and inlays thanks to the patented PERFORMANCE+ hot-stamping process

- Structural embossing effects for added depth and texture

- Material freedom: Suitable for steel and aluminum rims or plastic inserts

- High resistance to stone chipping, abrasion, chemicals, weathering, and UV light

- Elimination of manufacturing steps such as gloss turning

- Production-ready, efficient process for reducing CO2 emissions and scrap rates

- Optimally suited for recycled materials

- Innovative design elements also for use in the aftermarket

Project partners

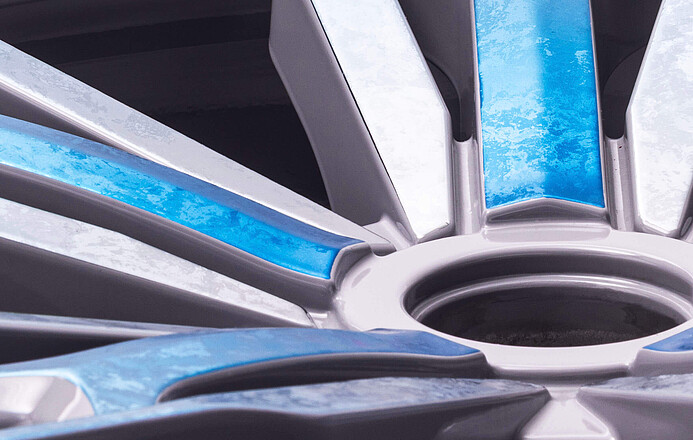

Hot stamping on steel rims

Steel wheels are becoming increasingly important: Due to their good CO2 footprint and 100% recyclability, their stability and for cost reasons. Partial decorations on metal and plastic inserts? Micro-embossing on the rim lacquer? Dark chrome or supermatte? Anything is possible when it comes to visual effects – of course in accordance with the strictest industry specifications. Together, this makes: Design diversity made by KURZ on steel rims from Magnetto Wheels and plastic inserts from ZANINI.

Project partners

KURZ as a solution partner

We strive for close collaboration with our customers along the entire value chain. That’s why we are constantly further developing our processes. For example, the optimized hot-stamping PERFORMANCE+ process can now also be used to economically decorate 3D geometries with a lower carbon footprint in series production.