Functional Foil Bonding (FFB) Adhesive

Compact light integration for complex geometries

Nowadays, automotive components increasingly contain touch sensors, LED foils, or other decorative functional elements. Integrating these sometimes sensitive materials is becoming increasingly challenging due to the ever more complex geometries of the components. KURZ provides the solution with its new Functional Foil Bonding (FFB) Adhesive process, which was specially developed for the automated bonding of sensitive labels and delicate surfaces. The technology, which requires neither heat nor pressure, is not only energy-efficient but also offers maximum flexibility for the design of 2D and 2.5D geometries. Thanks to UV curing of the transparent adhesive, downstream steps such as autoclaving are no longer necessary, and the components can be processed immediately.

Efficient technology, high process reliability

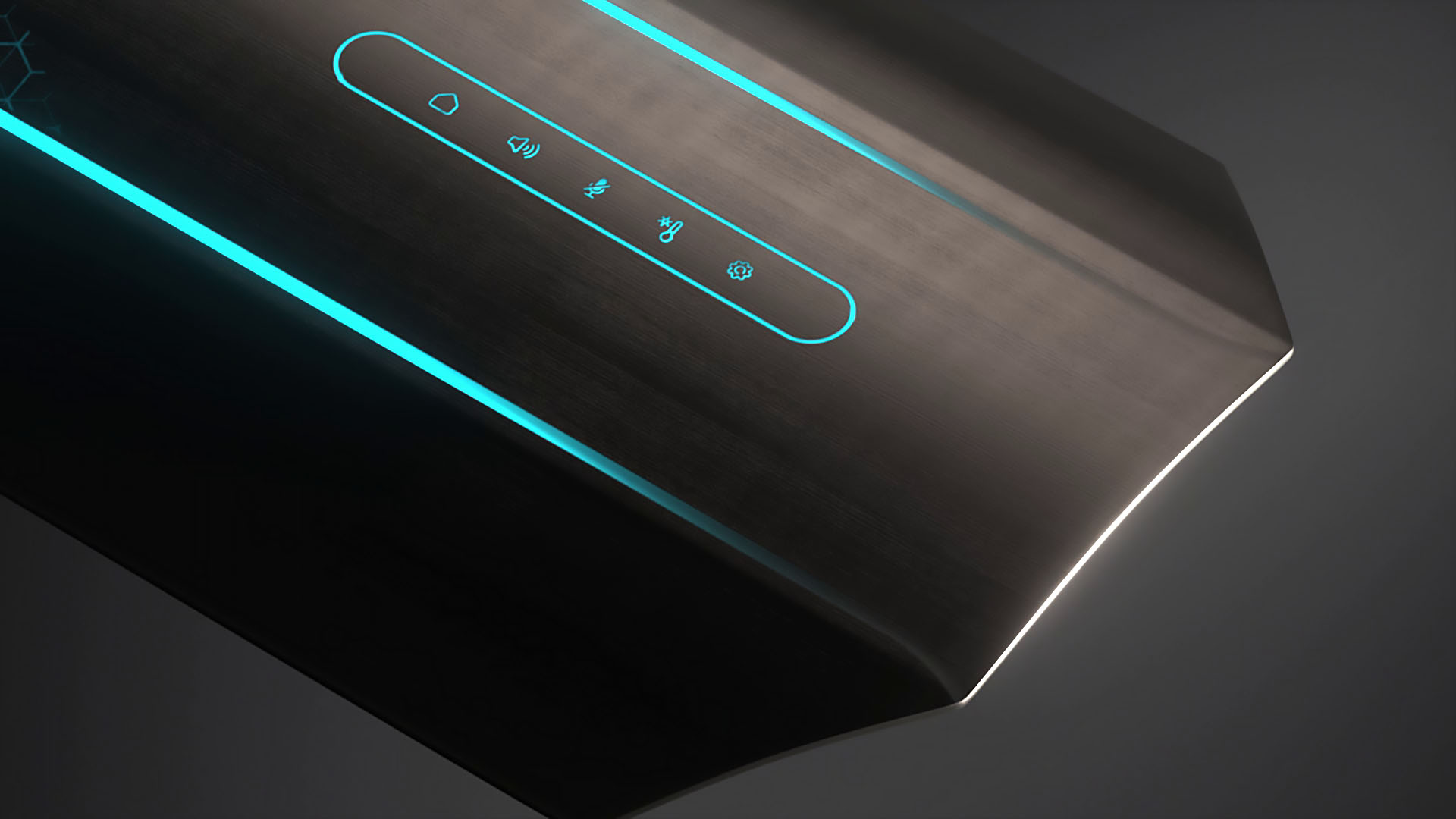

The advantages of the FFB Adhesive process are demonstrated in a cooperation project between KURZ and ams OSRAM, in which mini-LEDs are attached to a rear light component using the new process. This project utilizes the innovative ALIYOS™ technology from ams OSRAM, which is ideal for compact light integration in complex geometries. Another key advantage is the high brightness combined with low energy consumption.

- In the first step of the process, the plastic component is positioned in the designated holder. At the same time, the LED label is precisely placed in a designated position in the system, where it is picked up by a robotic arm.

- The robot arm first guides the label to a dispenser. Here, an optically transparent adhesive is applied to the label.

- Next, the prepared label is moved on, placed precisely on the component, and pressed down evenly to prevent any air pockets.

- This is followed by the final curing of the adhesive using UV light – a particularly gentle form of processing. In contrast to classic lamination processes, for example, the component can be removed immediately afterwards and used for further processing. As a post-mold procedure, the FFB Adhesive process also offers the possibility of optimizing the application process separately, thereby increasing the overall quality.

The advantages at a glance

- Precise control, short cycle times, and high process reliability through adhesive activation via UV light

- Gentle processing without thermal or mechanical stress

- Ideal for sensitive surfaces and materials such as touch sensors, LED labels, or electronics

- High degree of design freedom and segment-specific customization

- Reliable application on complex geometries

- Technology suitable for series production

- Turnkey solution: Process, system, adhesive, and touch sensor from a single source