RECOSYS® rPET

Before: Recycled pellets.

After: Technical textiles.

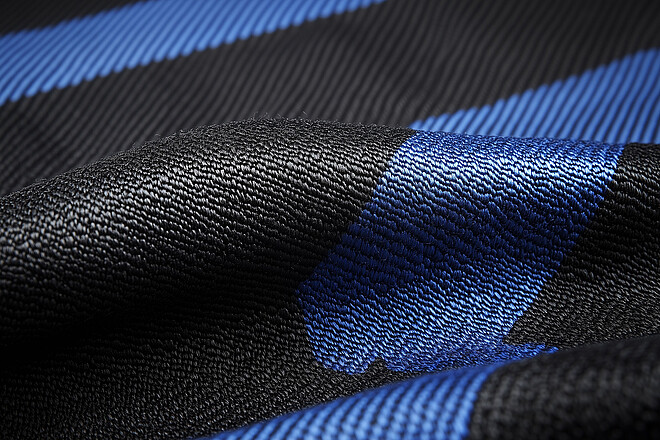

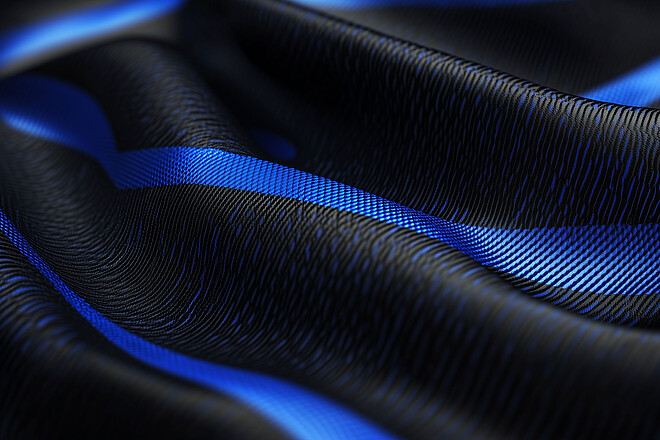

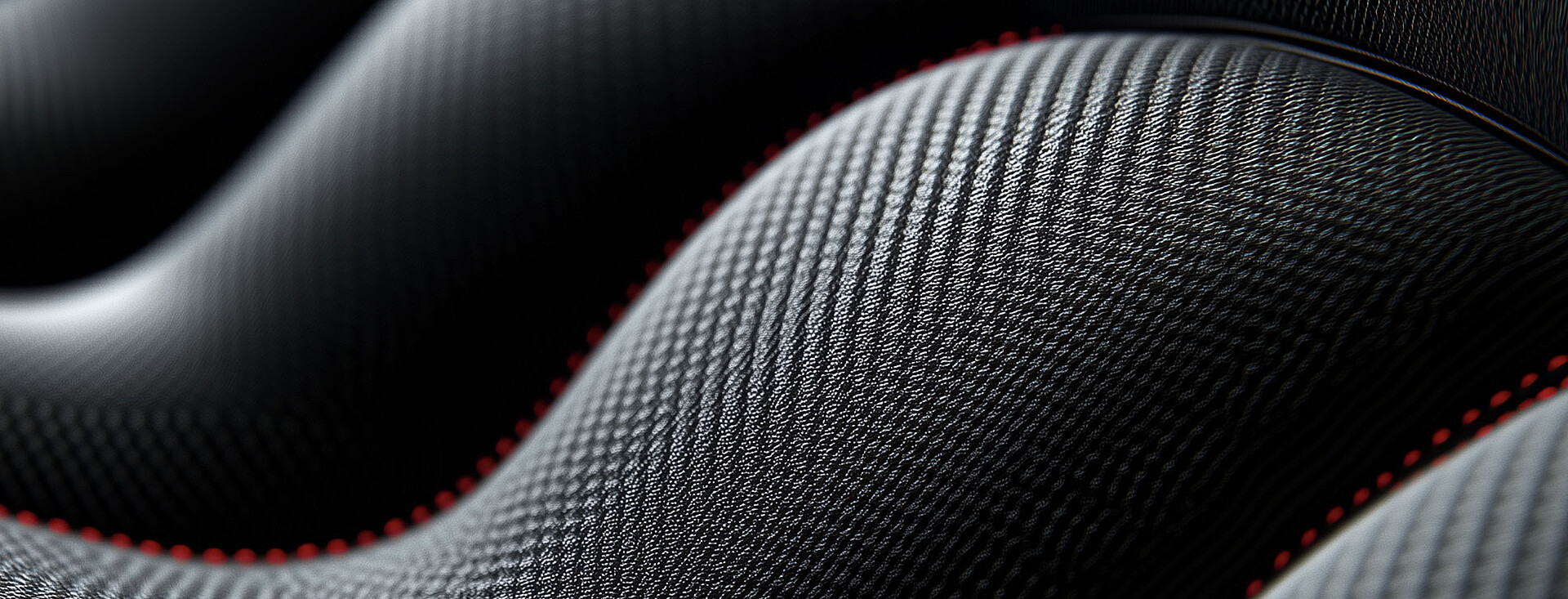

The best thing you can do with used PET carrier films from the graphics industry? Convert them into pure rPET – this can be used as a basis for fibers and the resulting technical textiles for the automotive industry, for example. A sustainable approach with a wide range of uses: For example, for the recoating and decoration of interior components such as instrument clusters and the like. Especially since, according to a proposal from the EU Commission, up to 25% of the plastic used for new cars should come from recycled sources in the future. rPET can help with this.

For efficient CO2 reduction:

the rPET evolution.

KURZ stands for value and sustainability along the entire process chain – from application to recycling.

RECOSYS® 2.0

Preparation of residual material with RECOSYS® 2.0 process

rPet material

Recovery of 100% unmixed Post Industrial Recyclate (PIR)

PET carriers

Single-variety collection of used transfer media

Transport

Transport to the in-house special recycling plant

Production

Further processing into sustainable fibers, for example

New products

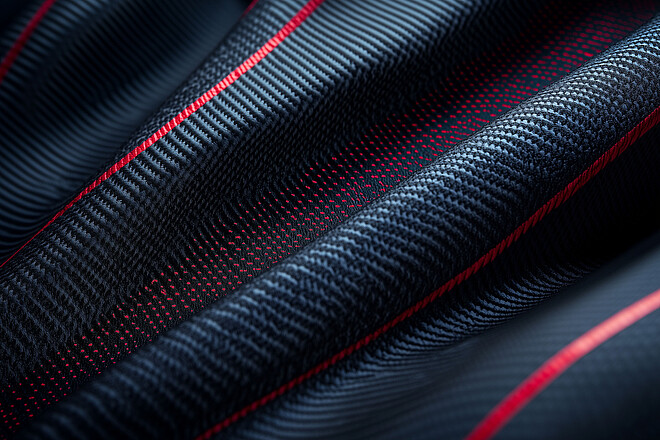

Wide range of applications as technical textiles in the automotive sector

Pro resources – contra scarcity.

Compared to the use of virgin PET, the recycled granulate RECOSYS® rPET can contribute to reducing the CO2 footprint. It supports short distances, reliable availability and transparency.

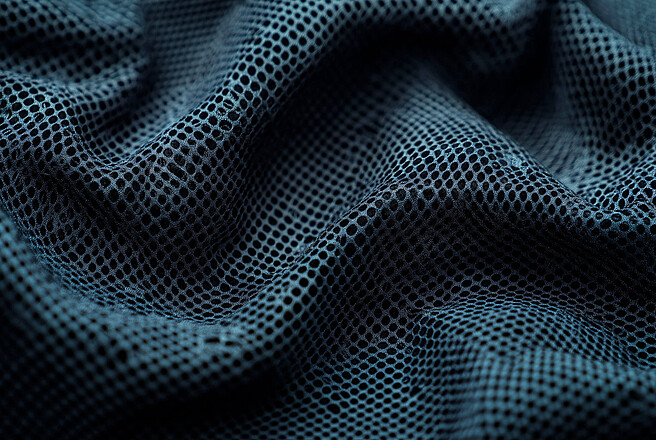

Supports sustainability. And new design ideas.

RECOSYS® rPET can be dyed and processed as new material – without compromising recyclability. Different structures or functional coatings? No problem at all. Ideal for high demands. On creativity and sustainability.

Made by KURZ. Made in Germany.

RECOSYS® rPET for the automotive industry:

- 100% recyclable

- Use of new plastic can be avoided

- CO2 footprint can be reduced

- Test material available

- Transparent and understandable

- Versatile usage

- Can be used for interior components