Front Design

A smart solution for autonomous driving

When it comes to automobile front designs, completely new rules apply. Materials must be tailored to the requirements of self-driving cars with regard to artificial intelligence, design, and durability. Front styles containing electronic and lighting elements. Sturdy surfaces boasting not only outstanding durability, but breathtaking depth effects and self-healing materials. Compositions supporting radar and LiDAR functions. The vehicles of tomorrow will communicate, operate, and react with other road users, and shape the streetscape of the future.

IMD with laser etching: Highlight for vehicle fronts

KURZ adds another extremely striking facet to the diverse front panel design variations, which is also suitable for very large components over 1,000 mm. An indium-based metallized front panel is laser engraved to enable additional lighting effects on closed surfaces. With this ingenious solution, special editions down to a quantity of 1 can be realized easily and economically whilst enabling series production.

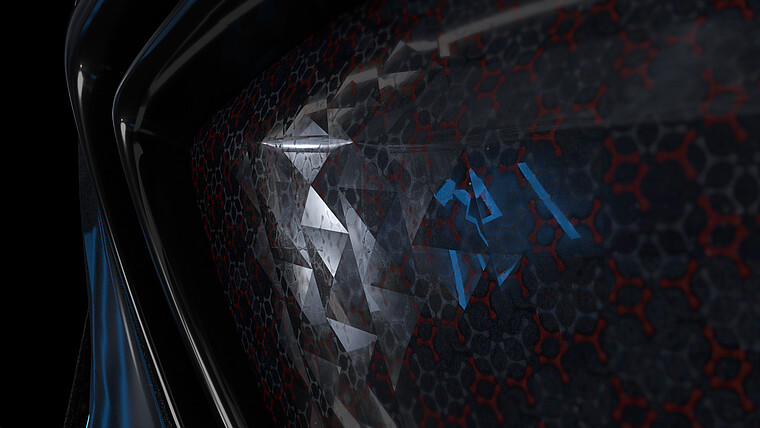

IMD with backlighting effects: Design and function perfectly combined

Light makes front panels bolder, more contemporary, and more personal. Increasingly large, they offer designers numerous opportunities to combine creativity with functionality. From day-night design and communication with other road users to branding elements such as logo displays - backlighting effects offer striking and new design options.

Your front panel options with IMD at a glance

- CO2 reduction through IMD decoration for closed large components

- Several process steps can be implemented in one machine unit, even DECOPUR®

- Numerous designs (wood look, metallization, BlackPanel, technical patterns, etc.) can be combined with day-night effects. Indium-based metallization is THE environmentally friendly alternative to electroplating

- 3D light effects for logo integration or light designs for environmental communication can be included

- Integration of touch operation possible

- NEW: Integration of heating solutions possible

- Supports autonomous driving technologies

DECOPUR® for PP components

NEW: DECOPUR® is now also available for the decoration of PP components.

3 steps - one process

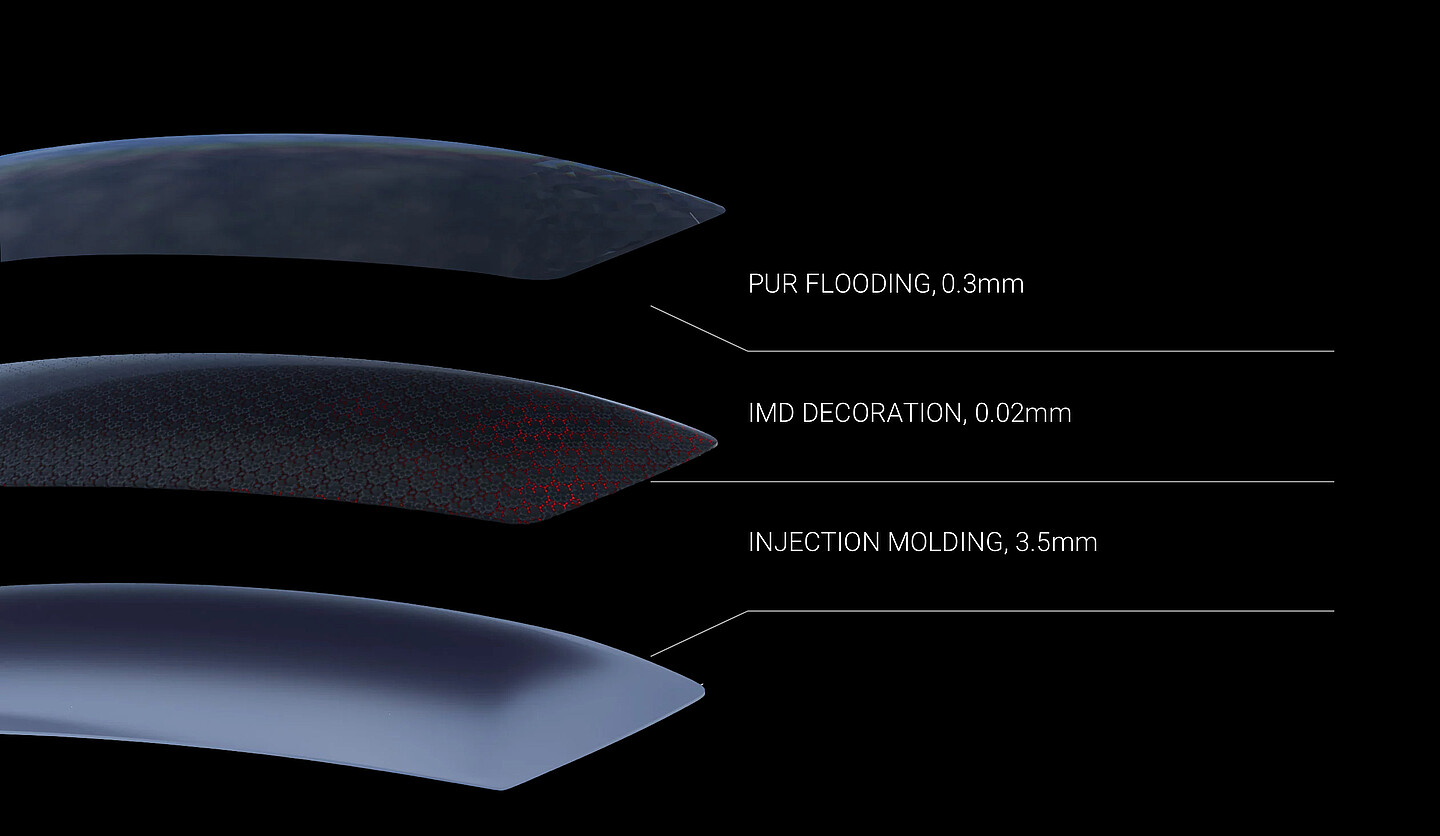

DECOPUR®

technological quantum leap

Smooth, aerodynamic and hazard-reducing surfaces, maximum functionality, and design options without equal – cars with these features will shape the streetscape of tomorrow. The cutting-edge technology of self-driving cars is hidden in the innovatively decorated front end, which is increasingly becoming the central brand element of the car. We at KURZ have worked out a wonderful solution for manufacturers and suppliers: DECOPUR®. It combines the best of two worlds:

In-Mold Decoration (IMD), with its flexibility and quality in the design of plastic and other surfaces, and its variety of options. Take advantage of countless opportunities to customize your automotive decoration

PUR (polyurethane) for crystal-clear surfaces that are extremely durable and self-healing. Crystal-clear polyurethane lends fantastic depth effects to surfaces, highlighting the decoration underneath

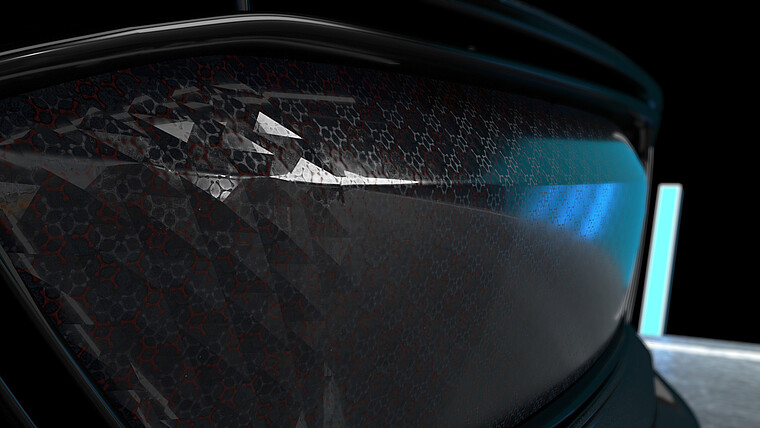

Sustainable metallization with chrome and indium

Sensational reflections combined with color, design, and real chrome looks are the latest trends from KURZ, in the interior as well as in the exterior. The incredible design variations offered by indium-based metallization can even be seamlessly and precisely transferred to components over 1,000 mm wide. Chrome and indium have another advantage: They are particularly suitable for shy tech designs and 5G technology. Backlighting provides additional orientation and design highlights.

The special features of indium and chrome-based metallization:

- THE environmentally friendly alternative to electroplating

- Ultra-thin decorative layer

- Consistent quality, even for large series

- Unlimited design freedom: Patterns and colors are just as possible as real chrome or indium optics, glossy, matte, semi-matte and brushed surfaces

- Supports technologies for autonomous driving

- Backlightable, therefore ideal for shy tech designs and touch operation

- Highly efficient customization with laser etching possible

- Can be used partially

- Lower CO2 footprint (reduced by up to 85%)

- Suitable for different types of plastic: ABS, PC/ABS, ASA, PP, PA12

- Chromium and indium are REACH-compliant and therefore not subject to authorization in the EU

- Can be used for recyclates

- The metallized components are easily recyclable